GOVERNORS

Speed Limits & Repair

If a Service Replacement Engine is used, check the top

governed speed using a tachometer, with the engine

operating on a completely assembled mower, to be sure

the blade tip speed will not exceed 19,000 feet per

minute. If necessary, change the governor spring or

adjust the top speed limit device, so the engine will not

exceed the recommended speed, based on blade length

as shown. See page 6 for adjustment procedure for

mechanical governor.

If a governor spring must be replaced, consult the

appropriate Illustrated Parts List. Choose the proper

governor spring by engine type number. AFTER A NEW

GOVERNOR SPRING IS INSTALLED, CHECK ENGINE

TOP GOVERNED SPEED WITH AN ACCURATE

TACHOMETER.

Run engine at half throttle to allow the engine to reach

normal operating temperature before measuring speed

with a tachometer. To account for tolerances, which may

be required by tachometer manufacturers, we suggest

that the top governed speed of the engine be adjusted at

least 200 R.P.M. lower than the maximum speeds

shown.

Since blade tip speed is a function of engine R.P.M.,

lower tip speeds require lower engine speeds.

The

chart

below

lists

various

lengths

of

rotary

lawnmower cutter blades, and the maximum blade

rotational speeds, which will produce blade tip speeds of

19, 000 feet per minute.

BLADE

MAXIMUM

LENGTH

ROTATIONAL R.P.M.

18"

4032

19"

3820

20"

3629

21"

3456

22"

3299

23"

3155

24"

3024

25"

2903

26"

2791

NOTE: For correct no load R.P.M. by model and type,

see engine sales manual. Note column.

MECHANICAL GOVERNOR

MODELS N, 6, 8 (CAST IRON)

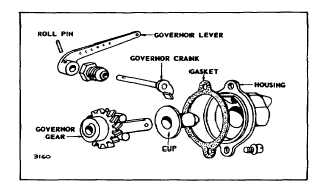

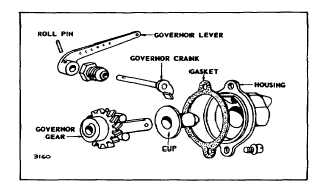

Disassembly

Loosen the two mounting screws to remove governor

housing. The cup can be pulled off the governor gear

and the gear will slide off the shaft.

See Fig. 4. To disassemble the governor crank, drive

the roll pin out at the end of the governor lever; remove

the governor crank bushing. Then pull governor crank

out of the housing.

Fig. 4. Governor Housing and Gear Assembly

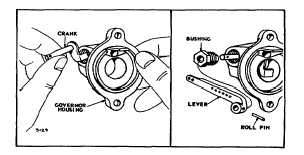

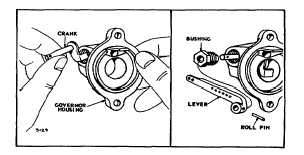

Re-Assembly

To assemble the governor crank, bushing and lever to

the housing, push the governor crank, lever end first, into

the housing. Slip the bushing onto the shaft:; then thread

the bushing into the housing and tighten securely. Place

the lever on the shaft with the governor crank in the

position shown in Fig. 5. Place the governor gear on

shaft in cylinder. Place gasket on governor housing;

then assemble governor housing to the cylinder and

tighten in place with two mounting screws.

Fig. 5 - Install Crank and Lever

2