GOVERNORS

General & Speed Limits

Section 5

GOVERNORS

THE PURPOSE OF THE GOVERNOR IS TO MAINTAIN

WITHIN CERTAIN LIMITS, A DESIRED ENGINE

SPEED, EVEN THOUGH THE LOAD MAY VARY.

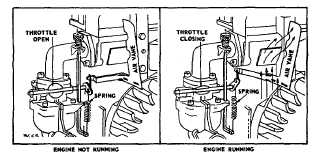

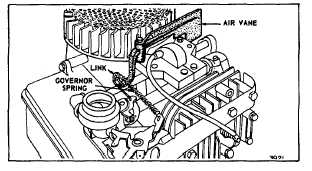

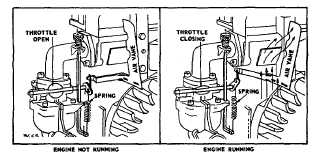

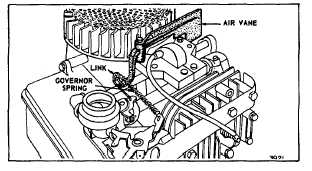

AIR VANE GOVERNOR

The governor spring tends to open the throttle. Air

pressure against the air vane tends to close the throttle.

The engine speed at which these two forces balance is

called the governed speed. The governed speed can be

varied by changing governor spring tension, Fig. 1, or

changing governor spring, Fig. 2.

Checking

Worn linkage or damaged governor springs should be

replaced to insure proper governor operation. If spring

or linkage is changed, check and adjust TOP NO LOAD

R.P.M., Fig. 1, or check TOP NO LOAD R.P.M., Fig. 2,

with engine assembled.

Fig. 1. Air Vane Governor (Typical)

Fig. 2. Air Vane Governor (Typical)

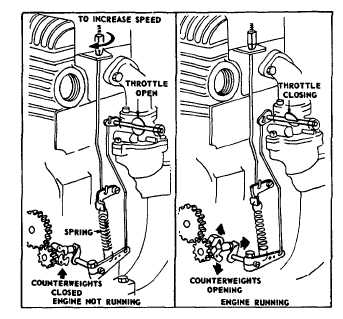

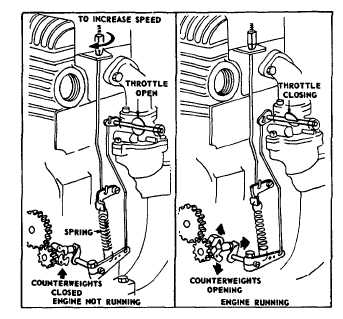

MECHANICAL GOVERNOR

The governor spring tends to pull the throttle open. The

force of the counterweights, which are operated by

centrifugal force, tends to close the throttle. The engine

speed at which these two forces balance is called the

governed speed. The governed speed can be varied by

changing governor spring tension or governor spring.

See Fig. 3.

Fig. 3. Mechanical Governor

GOVERNED SPEED LIMITS

To comply with specified top governed speed limits,

Briggs & Stratton supplies manufacturers with engines

using either calibrated governor springs or an adjustable

top speed limit. Calibrated springs or an adjustable top

speed limit will allow no more than a desired top

governed speed when the engine is operated on a rigid

test stand at our own Factory. However, the design of

the cutter blade, deck, etc., can affect engine speeds.

Therefore, the top governed speed should be checked

with tachometer when the engine is operated on a

completely assembled machine. If on a lawn mower, it

should be operated on a hard surface to eliminate cutting

load on the blade.

JUNE 1981

1