GOVERNORS

Repair & Adjustment

Re-Assembly

Insert governor shaft into governor bushing from inside

cylinder. Then slide governor lever on governor shaft

and slide lever down onto shaft slot. Slide on lever

clamp and start screw in adjusting slot on clamp. Torque

lever clamp screw to 15 in. lbs. (.17 mkp, 1.7 N•m).

Install oil slinger and governor gear assembly, sump

gasket and oil sump. Place non-hardening sealant on

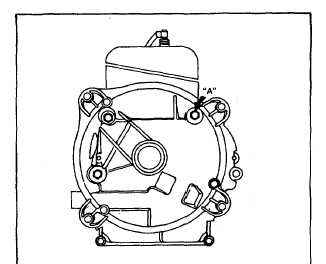

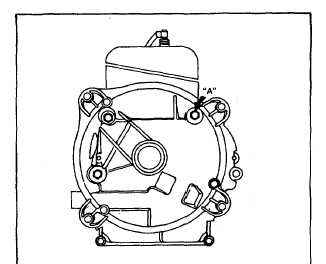

screw "A," Fig. 11, and tighten all sump screws.

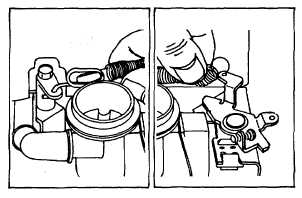

Fig. 11 Sealant on Screw

Adjustment

Loosen lever adjusting screw, Fig. 10. While holding

governor lever and governor clamp to the left

(counterclockwise), tighten lever adjusting screw to 15 in.

lbs. (.17 mkp, 1.7 N•m).

Replacement, Governor Shaft Bushing

When a new governor shaft bushing is pressed in, it

should be pressed in until 1/16" (1.58 mm) extends out

from crankcase. Finish ream with 19058 reamer using

Stanisol or kerosene for lubricant.

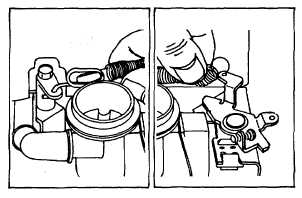

Installation, Governor Spring

Hold governor spring as shown in Fig. 12 with open end

of small loop down. Hook large loop in throttle link loop

as shown in Fig. 12 and pull loop toward throttle lever

until end of spring loop snaps on. Hook small loop in

throttle control lever as shown in Fig. 13.

Fig. 12. Installing

Fig. 13. Governor

Governor Spring

Spring Installed

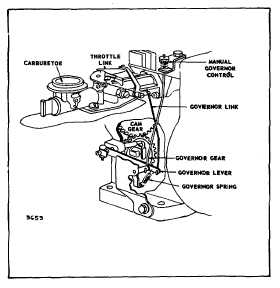

100000, 130000, 140000, 170000, 190000, 220000 and

250000 (Aluminum Cylinders)

Disassembly

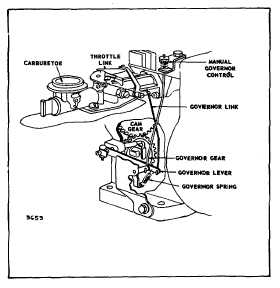

The governor used on the horizontal shaft models is

illustrated in Figs. 14 and 16. The governor used on the

vertical shaft models is incorporated with the oil slinger.

Figs. 15 and 16.

The only disassembly necessary is removing the

governor assembly as one unit from the shaft on the

crankcase cover on horizontal models. On vertical shaft

models, it is removed as part of the oil slinger. Further

disassembly is unnecessary.

Fig. 14. Horizontal Shaft

5