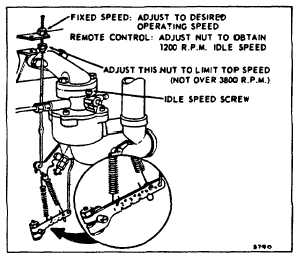

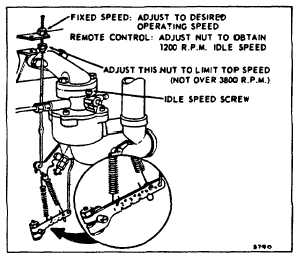

GOVERNORS

Speed Setting

MODEL SERIES 190000, 200000, 230000, 300000,

320000 (Cast Iron Cylinders)

For fixed speed operation, loosen lower stop nut. Adjust

top stop nut to obtain top no load governor R.P.M. as

shown in Engine Sales Manual, Note column. Tighten

lower stop nut. Fig. 24.

For remote control operation, adjust lower stop nut to

obtain top no load governed R.P.M. as specified in the

Engine Sales Manual, Note column. Fig. 24.

To adjust governor idle refer to Section 4, Governor

Controls and Carburetor Linkages.

Fig. 24

OBTAINING CLOSER GOVERNING

(Generator Applications Only)

Governor regulation to within two cycles of either 60 or

50 cycles can be obtained if the following procedure is

done:

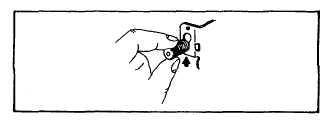

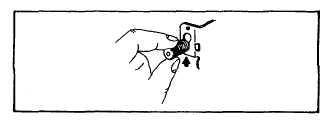

MODEL SERIES 100000, 130000

a.

1800 R.P.M., 60 cycle or 1500 R.P.M., 50 cycle

generators -- Push speed adjusting nut in and up to

release spring tension, Fig. 25. Start engine and pull

out on speed adjusting nut to the maximum length of

travel. Set engine speed to 2800 R.P.M. by bending

governor tang, Fig. 21. With engine still running,

return speed adjusting nut to slot and turn nut to

obtain 1875 R.P.M., 60 cycle, or 1600 R.P.M., 50

cycle, no load.

b.

3600 R.P.M., 60 cycle or 3000 R.P.M., 50 cycle

generators -- Push speed adjusting nut in and up to

release spring tension, Fig. 25. Start engine and pull

out on speed adjusting nut. Set engine speed to

4600 R.P.M. by bending governor tang, Fig. 21.

With engine still running, return speed adjusting nut

to slot and turn nut to obtain 3700 R.P.M., 60 cycle,

or 3100 R.P.M., 50 cycle, no load.

MODEL SERIES 140000, 170000, 190000, 220000,

250000 (Aluminum Cylinders)

a.

1800 R.P.M., 60 cycle or 1500 R.P.M., 50 cycle

generators -- Push speed adjusting nut in and up to

release spring tension, Fig. 25. Start engine and pull

out on speed adjusting nut. Set engine speed to

2600 R.P.M. by bending governor tang, Fig. 21.

With engine still running, return speed adjusting nut

to slot and turn nut to obtain 1875 R.P.M., 60 cycle

or 1600 R.P.M., 50 cycle, no load.

b.

3600 R.P.M., 60 cycle or 3000 R.P.M., 50 cycle

generators -- Push speed adjusting nut in and up to

release spring tension, Fig. 25. Start engine and pull

out on speed adjusting nut. Set engine speed to

4200 R.P.M. by bending governor tang, Fig. 21.

With engine still running, return speed adjusting nut

to slot and turn nut to obtain 3700 R.P.M., 60 cycle

or 3100 R.P.M., 50 cycle, no load.

Fig. 25

8