COMPRESSION

Cylinder Head

Section 6

COMPRESSION

COMPRESSION

Briggs & Stratton does not publish any compression

pressures, as it is extremely difficult to obtain an

accurate reading without special equipment.

It has been determined through extensive testing, a

simple and accurate indication of compression can be

made as follows:

Spin the flywheel counterclockwise (flywheel side)

against the compression stroke, a sharp rebound

indicates satisfactory compression. Slight or no rebound

indicates poor compression.

Loss of compression will usually be the result of the

following:

1.

The cylinder head gasket blown or leaking.

2.

Valves sticking or not seating properly.

3.

Piston rings not sealing, which would also cause the

engine to consume an excessive amount of oil.

Carbon deposits in the combustion chamber should be

removed every 100 to 300 hours of use (more often

when run at a steady load), or whenever the cylinder

head is removed.

Remove Cylinder Head and Shield

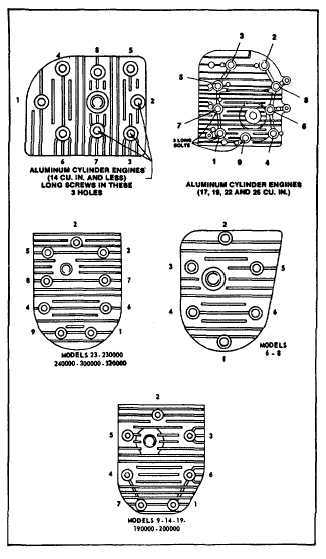

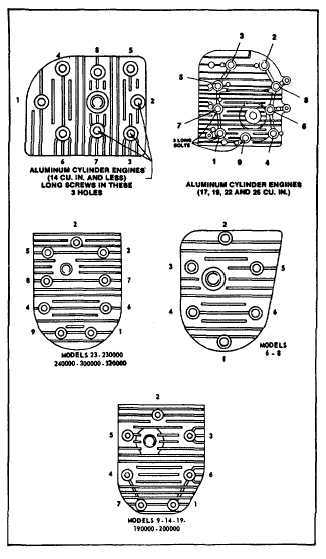

Always note the position of the different cylinder head

screws so that they may be properly reassembled. If a

screw is used in the wrong position, it may be too short

and not engage enough threads. It may be too long and

bottom on a fin, either breaking the fin, or leaving the

cylinder head loose.

CYLINDER HEAD TORQUE PROCEDURE

Assemble the cylinder head with a new head gasket,

cylinder head shield, screws and washers in their proper

places. (A graphite grease or part no. 93963 should be

used on aluminum cylinder screws.)

Do not use a sealer of any kind on gasket. Tighten the

screws down evenly by hand. Use a torque wrench and

tighten head bolts in the sequence shown, Fig. 1, and to

the specified torque in Table 1.

Do not turn one screw down completely before the

others, as it may cause a warped cylinder head.

Fig. 1. Cylinder Heads

JUNE 1981

1