COMPRESSION

Valve Guides & Seat Inserts

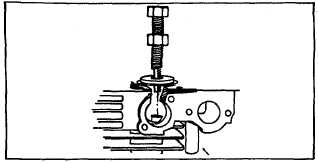

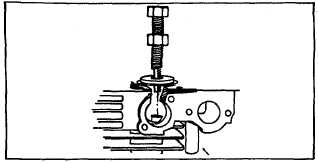

Fig. 10

Repairing Worn Aluminum or Sintered Iron Guides

Place piloted counterbore reamer, 19231, into worn

guide. Slide reamer guide, 19234, down shank of 19231

and center on valve seat, Fig. 9, Illus. 2. Place bushing

231218 next to reamer on reamer guide, Fig. 9, Illus. 2,

and mark reamer 1/16" (1.6 mm) above bushing.

Use Stanisol or kerosene to lubricate reamer while

turning clockwise. Continue reaming until mark on

reamer is flush with top of reamer guide bushing, 1-1/32"

(26.19 mm), Fig. 9, Illus. 3.

Installing Replacement Bushing

Clean out all chips. Place grooved end of service

bushing, 231218, into valve guide, Fig. 9, Illus. 4. Use

bushing driver, 19204, to press bushing into guide until

flush with top of guide or until it bottoms. Place reamer

guide bushing, 19234, on valve seat and slide finish

reamer, 19233, thru center of bushing. Fig. 9, Illus. 5.

Use Stanisol or kerosene as lubricant while turning

reamer clockwise. Continue reaming until reamer enters

tappet chamber. After reaming is done, continue to turn

reamer clockwise while removing. Clean out all chips

before reassembling engine.

Repairing Worn Valve Guides Using 19183 Reamer

and Reamer Guide Bushing 19192

Place piloted counterbore reamer, 19183 into worn

guide. Slide reamer guide bushing, 19192, down shank

of reamer and center in valve seat, Fig. 9, Illus. 2. Slide

replacement bushing, 230655, next to reamer shank on

reamer guide bushing. Mark reamer 1/16" (1.6 mm)

above bushing Fig. 9, Illus. 3. Use Stanisol or kerosene

to lubricate reamer while turning clockwise. Continue

reaming until mark on reamer is flush with top of

bushing. DO NOT REAM THROUGH THE WHOLE

GUIDE. Continue to turn reamer clockwise while

withdrawing reamer.

Installing Replacement Bushing 230655

Clean out all chips. Press in valve guide bushing,

230655, using bushing driver, 19204, until flush with top

of guide or until it bottoms. Fig. 9, Illus. 4. The bushing

230655 is finish reamed to size at the factory, no further

reaming is necessary, and a standard valve can be used.

NOTE: Cast iron engines use sintered (gray colored)

valve guide bushings. DO NOT REMOVE THESE

BUSHINGS. See reaming valve guide (230655 or

231218 bushing) to install service brass bushings.

CAUTION

Valve seating should be checked after bushing the

guide, and corrected if necessary by refacing the seat.

Valve Seat Inserts

Cast iron cylinder engines are equipped with an l exhaust

valve seat insert which can be removed and a new insert

installed. The intake side must be counterbored to allow

installation of an intake valve seat insert. Fig. 12, 13 &

14.

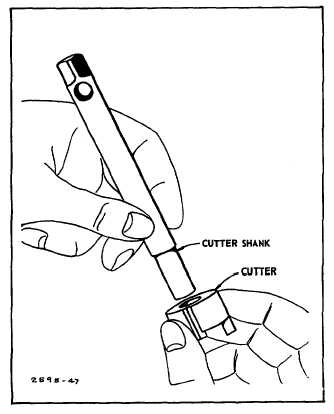

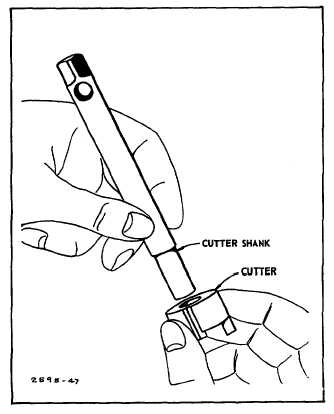

Fig. 12 - Inserting Cutter Shank

5