COMPRESSION

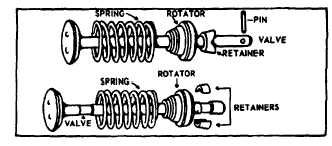

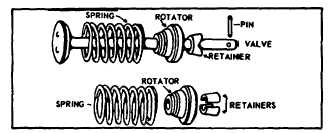

Stellite® Valves & Rotators

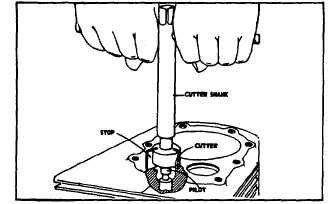

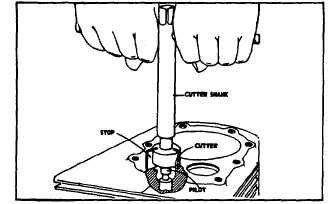

Fig. 21 - Counterboring for Valve Seat

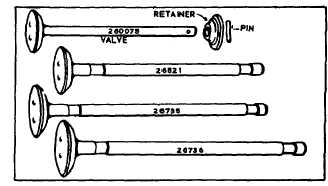

Valves, Valve Conversions

The life of a valve is considered to be the period of time

the valve will operate before repair or replacement is

necessary. The life of a standard exhaust valve is often

shortened because of burning, which occurs when

pieces of combustion deposit lodge between the valve

seat and valve face, preventing the valve from closing

completely. This is most likely to occur on engines which

are operated at constant speed and constant load, for

long periods of time. Exhaust valve life can be extended

by using:

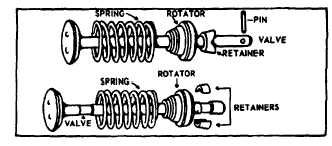

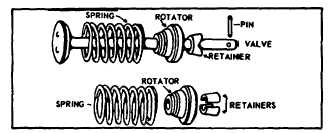

1.

A Rotocap (Valve Rotator), which turns the exhaust

valve a slight bit on each lift, wiping away any

deposits which tend to lodge between the valve face

and seat, or,

2.

A Stellite® Exhaust Valve which has a greater

resistance to heat.

Standard Valve and Rotocap

Stellite® Valve Only

Stellite® valve and Rotocap

Use Table 5 below, Table 6 on page 10 or Table 7 on

page 11 for Part Numbers.

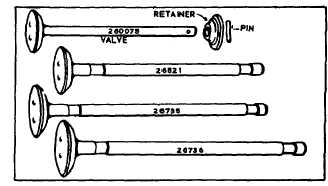

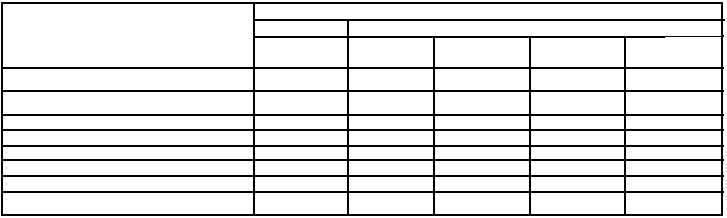

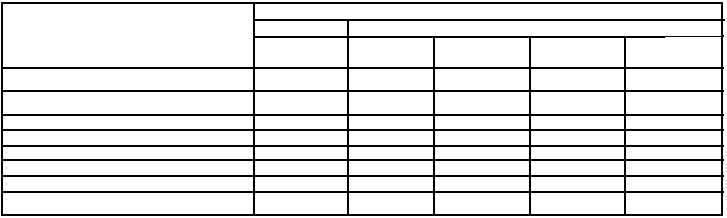

TABLE NO. 5

STELLITE® VALVE AND ROTOCAP CONVERSION

ROTOCAP ONLY CONVERSION

STELLITE®

BASIC MODEL SERIES

VALVE

SPRING

ROTOCAP

RETAINER

PIN

ALUMINUM CYLINDER

60000*, 80000*, 82000*, 92000*, 94000*

260443

26826

292259

230127

230126

100000, 130000260860

26826

292259

230127

230126

140000, 170000, 190000, 200000, 250000

390420

26828

292260

93630

CAST IRON CYLINDER

14, 19, 190000, 200000

26735

26828

292260

68283

23, 230000

261207

26828

292260

68283

240000, 300000, 320000

261207

26828

292260

68283

(Stellite® Std.)

*To use Rotocap only #26973 standard valve must be used.

NOTE: Rotocap not used with LP Gas on 6, 8 and 10 cu. in. engine.

9