TM 5-4240-5501-148P

ALTERNATOR

11/2 Amp

NOTE: Ground wire or rectifier assembly must not touch

the engine during this test.

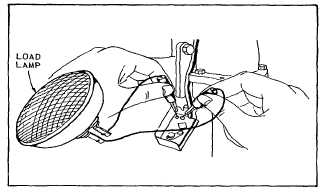

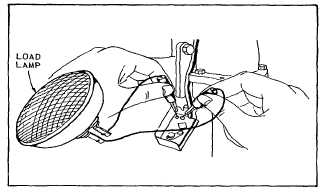

Start engine. With engine running, pierce stator wires

with probes from load lamp or touch terminals in rectifier

box. Fig. 154 and 155. If load lamp lights, the stator is

satisfactory. If load lamp does not light, the flywheel

magnet or stator is inoperative. The flywheel should be

examined to be sure magnet is charged. If required,

replace flywheel or the stator.

Fig. 154 Testing Stator

Fig. 155 Testing Stator (Alternator Style)

Replacing Defective Stator

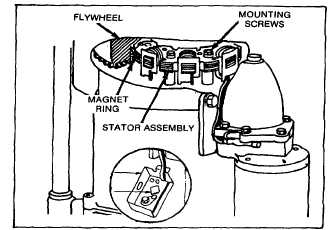

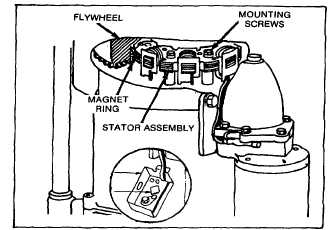

Remove the blower housing, rotating screen, clutch

assembly and flywheel. Note and remember location of

stator wires, under one coil spool, then between starter

and drive unit housing as shown in Fig. 156. Remove

ground wire or rectifier assembly from starter drive

housing. Remove the two stator mounting screws and

bushings.

Fig. 156 Stator Assembly Location

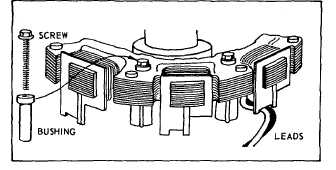

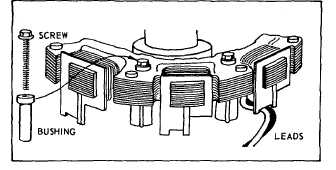

Install new stator assembly with stator mounting screws

and bushings. Be sure leads are properly positioned as

shown in Figure 157. While tightening mounting screws,

push stator toward crankshaft to take up clearance in

bushing. Torque mounting screws 18 to 24 inch pounds

(1.6 to 2.1 Nm). Before re-assembly, locate stator wires

against cylinder in order to clear ring gear and flywheel.

Attach ground wire or rectifier assembly to drive housing.

Replace flywheel and torque clutch housing as noted on

specification chart. Re-assemble rotating screen and

blower housing.

Fig. 157 Assembling Stator

Testing Rectifier

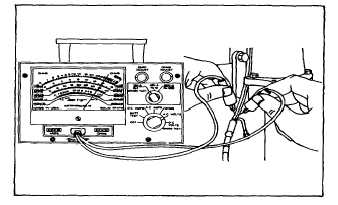

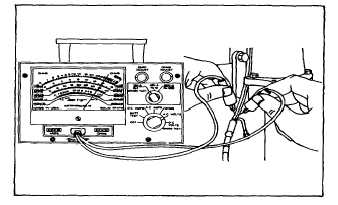

Do not start engine. Use the #19236 VOA meter to test

resistance from charging terminal to ground, as shown in

Fig. 158 or 159. Now reverse test leads and recheck.

One way there should be a meter reading. The other

way there should not be a meter reading. The actual

meter readings are not important. If the meter shows a

reading both ways, or neither way, the rectifier is

defective. Replace rectifier.

49