TM 5-4240-5501-148P

ALTERNATOR

11/2 Amp

1-1/2 AMP ALTERNATOR Used on Model Series

130000

The integral 1-1/2 ampere alternator, with solid state

rectifier, is designed for use with a compact battery. A

12 ampere hour battery is suggested for warm

temperature operation and a 24 ampere hour battery

should be used in cold service.

The alternator is rated at 3600 RPM. At lower speeds

available output is reduced.

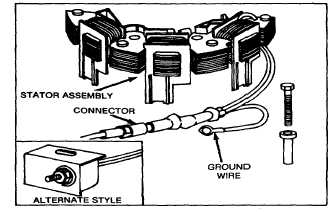

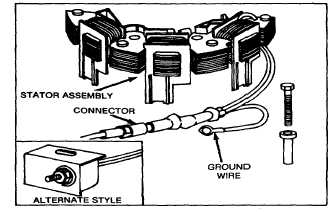

Fig. 150 - Alternator Assembly

WHEN CHECKING ALTERNATOR COMPONENTS,

MAKE THE TESTS IN THE FOLLOWING SEQUENCE:

CHECKING

1-1/2

AMP.

NON-REGULATED

ALTERNATOR

Condition Found (Battery Run Down)

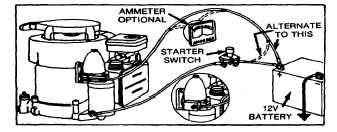

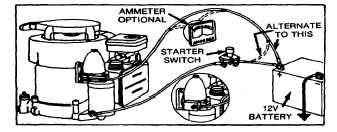

Check battery polarity. Negative (-) side of battery

should be grounded to engine or frame: positive (+) side

of battery to starter motor and alternator charge lead.

Figure 151. If reversed, rectifier will be damaged.

Fig. 151 - Typical Wiring Installation

Testing for Output

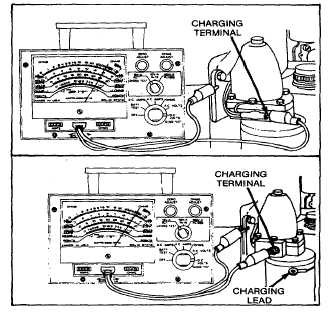

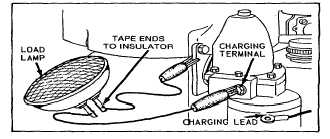

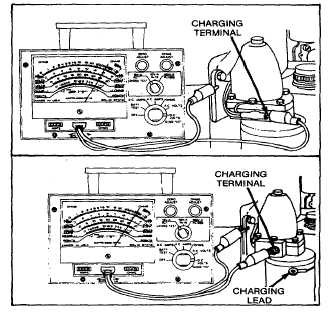

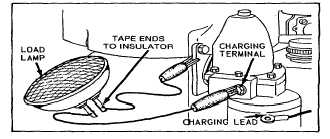

Disconnect connector or charging lead from charging

terminal. Fig. 152 and 153. Do not allow terminal on

charging lead to touch engine or equipment. Clip 12 volt

load lamp between charging terminal and ground. Start

engine. if lamp lights, alternator is functioning. If lamp

does not light, alternator system is defective. The same

test may be performed using 19236 Briggs & Stratton

VOA meter.

Fig. 152 - Checking Output

Fig. 153 - Checking Output, (Alternate Style)

Testing Stator

Unplug connector or disconnect charging lead from

battery and rectifier assembly on alternate style.

Remove screw from ground wire or rectifier assembly

from starter motor. Turn rectifier assembly to expose

wires attached to soldered terminals on alternate style.

48