ALTERNATOR

Dual Circuit - Fuse Type

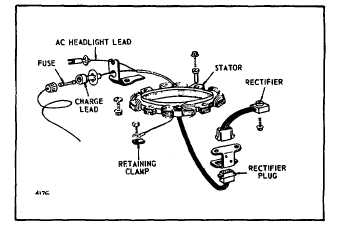

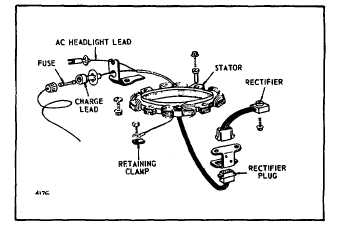

Dual Circuit Alternator with Fuse

This efficient gear drive, 12 volt battery powered starter

system is compact and powerful. It is available with

either a rope or rewind auxiliary starter. Recommended

battery sizes range from 20 ampere hour for warm

temperature service to 40 ampere hour in coldest

service.

Fig. 175 - Alternator Assembly

DUAL CIRCUIT ALTERNATOR

The dual circuit alternator is actually two separate

alternator systems. A single ring of magnets inside the

flywheel supplies the mag-netic field for both of them.

One alternator system uses a solid state rectifier and

provides battery charging current. The other alternator

system feeds alternating current directly to the lights.

Since the two are electrically inde-pendent, use of the

lights does not reduce the charge going into the battery.

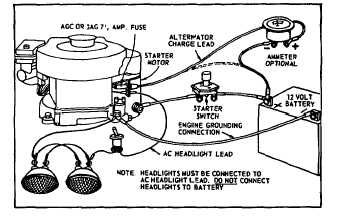

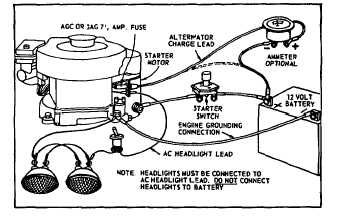

Fig. 176 - Typical Wiring Installation

The battery is not used for the lights, so lights are

available even if the battery is disconnected or removed.

Current for the lights is available as long as the engine is

running. The output depends upon engine speed.

Twelve-volt lights with a total rating of 60 to 100 watts

may be used. With lights rated at 70 watts, the voltage

rises from 8 volts at 2400 RPM to 12 volts at 3600 RPM,

so the brightness of the light changes with the engine

speed.

The current from the battery charging alternator is

unregulated and is rated at 3 amperes. The output rises

from 2 amperes at 2400 RPM to 3 amperes at 3600

RPM.

There are two external connections. The battery

charging current connection is made through a 7.5

ampere fuse mounted in a fuse holder beside the starter

motor. Current for the lights is available at a plastic

connector located below the fuse-holder. The two

connections are differ-ent so they cannot be accidentally

interchanged. The fuse protects the 3 amp charging

alternator and rectifier from burnout due to improper

(reverse polarity) battery connections. The 5 amp

lighting alternator does not require a fuse as a short

circuit in its output will not damage it. The return circuit

for both alternators is through ground to the engine

block. The alternator uses less than 0.2 horsepower.

CHECKING DUAL CIRCUIT ALTERNATOR

Fuse Blown

Check if battery polarity is correct: Negative (-) side of

battery should be grounded to engine or frame; positive

(+) side of battery to (fused) alternator output lead.

Figure 177. If reversed, correct and put in new fuse.

WHEN CHECKING ALTERNATOR COMPONENTS,

MAKE THE TESTS IN THE FOLLOWING SEQUENCE:

BATTERY RUNS DOWN

Testing Alternator Charging Output

Install ammeter in series with charging lead, as in Figure

177. Start engine. Ammeter should indicate charge.

The charge rate is dependent upon the condition of the

battery.

55