ALTERNATOR

Dual Circuit- Fuse Type

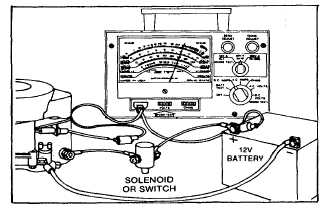

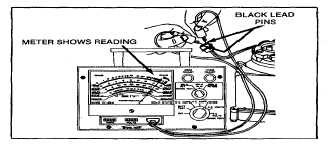

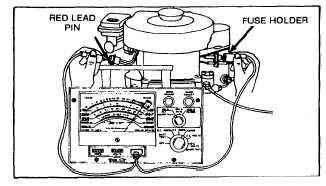

Fig. 177 - Testing Alternator Charging Output

If VOA meter shows no reading, test stator and rectifier.

Testing for Short in Stator or in Rectifier

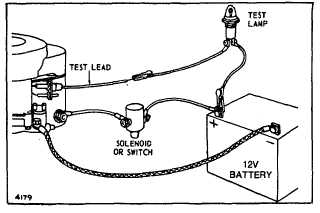

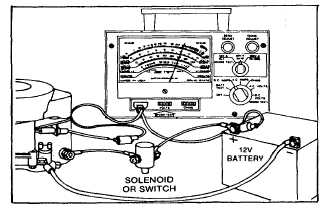

Disconnect charging lead from battery, and connect

small test lamp in series between battery positive

terminal and fuse cap, as shown in Figure 178. DO NOT

START ENGINE. Test lamp should not light. If it does

light, stator’s charging lead is grounded or rectifier is

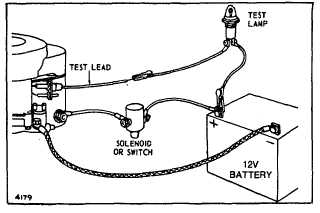

defective. Unplug rectifier plug under blower housing.

See Figure 179. If test light goes out, rectifier is

defective. If test light does not go out, stator charging

lead is grounded.

Fig. 178 - Testing for Short in Stator or Rectifier

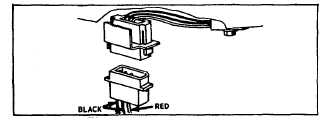

Fig. 179 - Rectifier Plug

Testing Stator Charging Coils

If ‘”short” test indicates stator charging lead is grounded,

remove blower housing, flywheel, starter motor and

retaining clamp (see figure 175) and examine length of

red lead for damaged insulation or obvious shorts on

lead. If bare spots are found, repair with electrical tape

and shellac. If short cannot be repaired, replace stator.

Charging lead should also be checked for continuity as

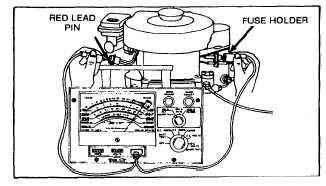

follows: Use multimeter, set on ohm Rx1 scale. Touch

one test prod to lead at fuse holder. Touch other test

prod to red lead pin in plastic connector: See Figure 180.

Unless the meter shows continuity, the charging lead is

open and the stator must be replaced.

Fig. 180 - Checking Charging Lead for Continuity

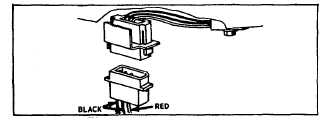

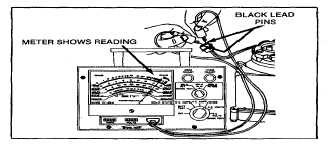

The charging coils should be checked for continuity as

follows: Using the multimeter, touch one test prod on

each of the black lead pins as shown in Figure 181.

Unless the meter shows continuity, charging coils are

defective and stator must be replaced. Test for

grounded charging coils by touching one test prod to a

clean “ground” surface on the engine and touching the

other test prod on each of the black lead pins as shown

in Figure 182. If the meter shows continuity, the

charging coils are grounded and stator must be replaced.

Fig. 181 - Checking Charging Coil Continuity

56