PISTONS - RINGS - RODS

Checking

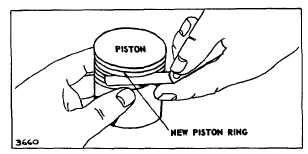

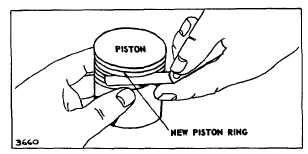

To do so, clean carbon from top ring groove. Place a

NEW ring on the groove, check the remaining space in

the groove with a feeler gauge. Fig. 5. If a .007" (0.18

mm) feeler gauge can be inserted (all models), the

piston is worn and should be replaced.

Fig. 5. Checking Ring Grooves

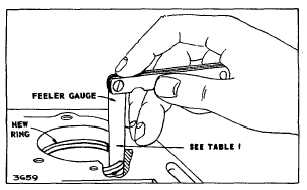

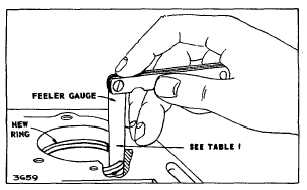

Check Rings

To check rings, first clean all carbon from the ends of the

rings and from the cylinder bore. Insert old rings one at

a time one inch down into the cylinder. Check gap with

feeler gauge. Fig. 6. If ring gap is greater than shown in

Table No. 1, the ring should be rejected.

Fig. 6. Checking Ring Gap

NOTE: Do not deglaze cylinder walls when installing

piston rings in aluminum cylinder engines.

Chrome Rings

NOTE: Chrome ring sets are available for all current

aluminum and cast iron cylinder models, no honing or

deglazing is required. The cylinder bore can be a

maximum of .005" (0.13 mm) oversize when using

chrome rings. See Service Bulletin 479 or Engine Parts

List.

TABLE NO. 1

RING GAP REJECTION SIZE

BASIC MODEL SERIES

COMP.

RING

OIL

RING

ALUMINUM CYLINDER

Inc

h

Mm

Inc

h

Mm

6B, 60000, 8B, 80000

82000, 92000, 110000, 111000

.035

0.80

.045

1.14

100000, 130000

140000, 170000, 190000, 250000

CAST IRON CYLINDER

Inc

h

Mm

Inc

h

Mm

5, 6, 8, N, 9

14, 19, 190000

200000, 23

.030

0.75

.035

0.90

230000, 240000

300000, 320000

TABLE NO. 2

CONNECTING ROD REJECT SIZES

BASIC MODEL SERIES

CRANK PIN

BEARING

PISTON PIN

BEARING

ALUMINUM CYLINDER

Inch

Mm

Inch

Mm

6B, 60000

.876

22.25

.492

12.50

8B, 80000

1.001

25.43

.492

12.50

82000, 92000, 110000

1.001

25.43

.492

12.50

100000

1.001

25.43

.555

14.10

130000

1.001

25.43

.492

12.50

140000, 170000

1.095

27.81

.674

17.12

190000

1.127

28.63

.674

17.12

220000, 250000

1.252

31.80

.802

20.37

CAST IRON CYLINDER

Inch

Mm

Inch

Mm

5

.752

19.10

.492

12.50

6, 8, N

.751

19.08

.492

12.50

9

.876

22.25

.563

14.30

14, 19, 190000

1.001

25.43

.674

17.12

200000

1.127

28.63

.674

17.12

23, 230000

1.189

30.20

.736

18.69

240000

1.314

33.38

.674

17.12

300000, 320000

1.314

33.38

.802

20.37

Check Connecting Rod

If the crankpin bearing in the rod is scored, the rod must

be replaced. Rejection sizes of crankpin bearing hole

and piston pin bearing hole are shown in Table No. 2.

Pistons pins .005" (0.13 mm) oversize are available in

case the connecting rod and piston are worn at the

piston pin bearing. If, however, the crankpin bearing in

the connecting rod is worn, the rod should be replaced.

Do not attempt to "file" or "fit" the rod.

Check Piston Pin

If the piston pin is worn .0005" (.01 mm) out of round or

below the rejection sizes listed below, it should be

replaced. Table No. 3.

2