PISTONS - RINGS - RODS

Assembly

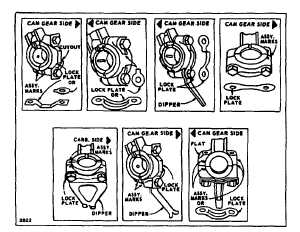

Install piston, connecting rod, and dipper. Piston

identification mark "F" and notch at top of piston must be

toward flywheel side. Torque connecting rod screw per

Table No. 4. Move connecting rod back and forth on

crankpin to be sure it is free.

Install Piston and Rod Assembly

All Models Except 300000 and 320000

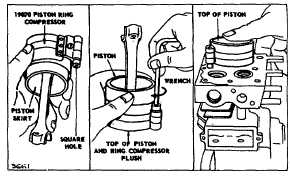

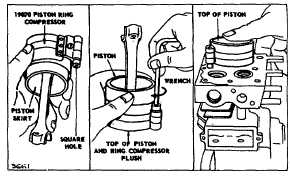

Place the connecting rod and piston assembly with rings

compressed into the cylinder bore, Fig. 10. Push piston

and rod down into the cylinder. Oil the crankpin of the

crankshaft. Pull the connecting rod against the crankpin

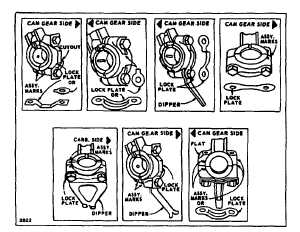

and assemble the rod cap so assembly marks align. Fig.

11.

NOTE: Some rods do not have assembly marks as rod

and cap will fit only in one position. Use care to ensure

proper installation.

Fig. 10. Install Piston Assembly

NOTE: Some rods may have flat washers under cap

screws; remove and discard prior to installing rod.

Fig. 11. Connecting Rod Installation

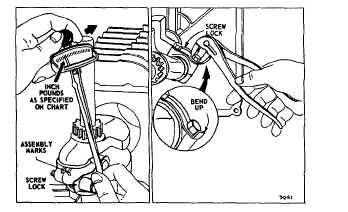

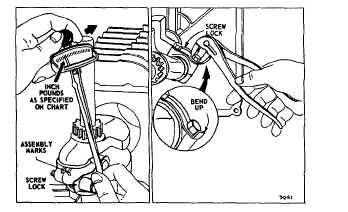

Assemble the cap screws and screw locks with oil dipper

(if used). Tighten cap screws to torque shown in Table

No. 4. Fig. 12. Rotate the crankshaft two revolutions to

be sure rod is correctly installed.

If rod strikes, connecting rod has been installed wrong or

cam gear is out of time. If crankshaft operates freely

bend screw locks against screw heads. Fig. 12.

Fig. 12. Bending Screw Locks

TABLE NO. 4

CONNECTING ROD CAP SCREW TORQUE

BASIC MODEL SERIES

AVERAGE TORQUE

ALUMINUM CYLINDER

Inch

Pounds

Kilogra

m Meter

Newton

Meter

6B, 60000

100

1.2

11.3

8B, 80000

100

1.2

11.3

82000,

92000,

110000,

111000

100

1.2

11.3

100000, 130000

100

1.2

11.3

140000, 170000, 190000

165

1.9

18.7

250000

185

2.1

21.0

CAST IRON CYLINDER

Inch

Pounds

Kilogra

m Meter

Newton

Meter

5, 6, N, 8

100

1.2

11.3

9

140

1.6

15.8

14

190

2.2

21.5

19, 190000, 200000

190

2.2

21.5

23, 230000

190

2.2

21.5

240000, 300000, 320000

190

2.2

21.5

NOTE: Tighten rod screws securely. After tightening rod

screws, rod should be able to move sideways on

crankpin of shaft. A torque wrench must be used to

prevent loose or overtight cap screws which results in

breakage and/or scoring of rod. Fig. 12.

4