PISTONS - RINGS - RODS

Assembly

TABLE NO. 3

PISTON PIN REJECTION SIZE

BASIC MODEL SERIES

PISTON PIN

PIN BORE

ALUMINUM CYLINDER

Inch

Mm

Inch

Mm

6B, 60000

.489

12.42

.491

12.47

8B, 80000

.489

12.42

.491

12.47

82000, 92000, 110000

.489

12.42

.491

12.47

100000

.552

14.02

.554

14.07

130000

.489

12.42

.491

12.47

140000, 170000, 190000

.671

17.04

.673

17.09

220000, 250000

.799

20.29

.801

20.35

CAST IRON CYLINDER

Inch

Mm

Inch

Mm

5, 6, 8, N

.489

12.42

.491

12.47

9

.561

14.25

.563

14.30

14, 19, 190000

.671

17.04

.673

17.09

200000

.671

17.04

.673

17.09

23, 230000

.734

8.64

.736

18.69

240000

.671

17.04

.673

17.09

300000, 320000

.799

20.29

.801

20.35

Assemble Piston and Connecting Rod

The piston pin is a push fit in both piston and connecting

rod. On models using a solid piston pin, one end is flat,

the other end is recessed. Other models use a hollow

pin.

Place a pin lock in the groove at one side of the piston.

From the opposite side of the piston, insert the piston

pin, flat end first with solid pin, either end with hollow

pins, until it stops against the pin lock. Fig. 3. Use a thin

nose pliers to assemble the pin lock in the recessed end

of the piston. Be sure the locks are firmly set in the

grooves.

Assemble Rings to Piston

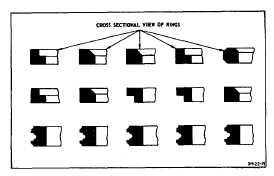

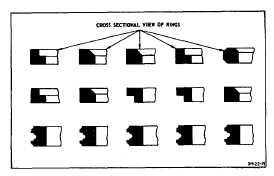

In Fig. 7, are shown the various rings and the proper

position of each. Note especially the center compression

ring. The scraper groove should always be down toward

the piston skirt. Be sure the oil return holes are clean

and carbon is removed from all grooves. NOTE: Install

expander under oil ring, when required.

Fig. 7. Position of Rings

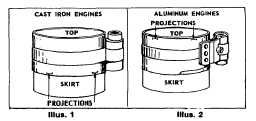

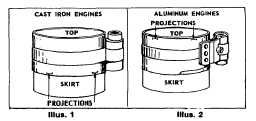

Oil the rings and piston skirt, then compress rings with

ring compressor (part 19070 or 19230). On all cast iron

models, use ring compressor (19070) as illustrated in

Fig. 8. Illustration 1. On all aluminum engines, use

compressor (19070) as illustrated in Fig. 8. Illustration 2.

NOTE: When using 19230 (2 band) ring compressor,

use as shown in Fig. 8, Illus. 1 on all engines.

Fig. 8. Compression Rings

Turn the piston and compressor upside down on the

bench and push downward, so the piston head and edge

of compressor band are even while tightening the

compressor. Draw the compressor up tight to fully

compress the rings, then loosen the compressor very

slightly. Do not attempt to install piston and ring

assembly without ring compressor.

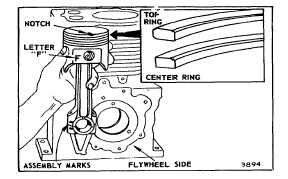

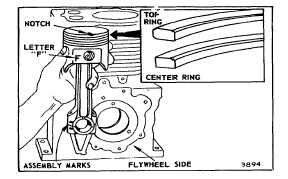

NOTE: The pistons used in the 220000 and 250000

engines have a notch as shown in Fig. 9. The notch

must face the flywheel side of the cylinder when

installed.

Installing Piston and Connecting Rod Models 300000

and 320000

The piston has an identification mark "F" located next to

piston pin bore. When assembling piston to the

connecting rod, the letter "F" on the piston must appear

on the same side as the assembly mark on the

connecting rod. Assembly mark on rod is also used to

identify rod and cap alignment. Install piston rings as

illustrated in Fig. 9.

Fig. 9. Assemble Piston to Rod

3