TM 5-4240-501-14&P

CRANKSHAFTS & CAM GEARS

Removal

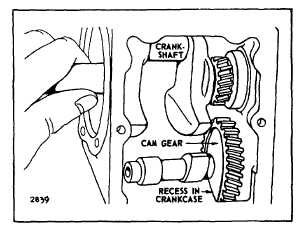

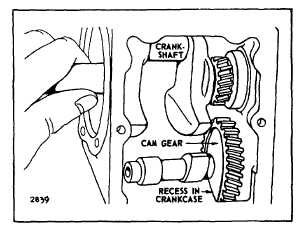

Fig. 4. Remove or Install Crankshaft

Model Series 9, 14, 19, 23, 200000, 230000

Plain Bearings

Remove crankshaft cover. Rotate crankshaft to

approximate position shown in Fig. 2. Pull out crankshaft

from P.T.O. side, twisting slightly, if necessary, to clear

cam gear.

Model Series 9, 14, 19, 23, 190000, 200000, 230000,

240000, 300000, 320000 Ball Bearings

NOTE: On 240000, 300000, 320000, piston and rod

must be removed from engine.

Remove crankcase cover and bearing support. Rotate

crankshaft to position shown, Fig. 2. On some models, it

may be necessary to position crankshaft approximately

180 from position shown in Fig. 2. Pull crankshaft out,

turning as needed to remove crankshaft.

To remove cam gear from all cast iron models, except

the 300000 and 320000, use a long punch to drive the

cam gear shaft out toward the magneto side. (Save

plug.) Fig. 3. Do not burr or peen end of shaft while

driving out. Hold cam gear while removing punch so

gear does not drop and nick.

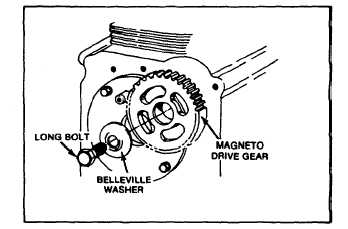

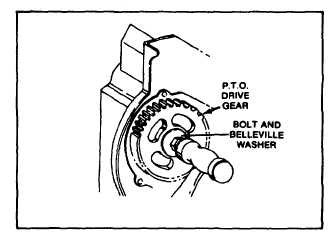

Model Series 300400, 320400

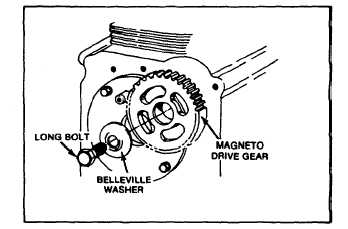

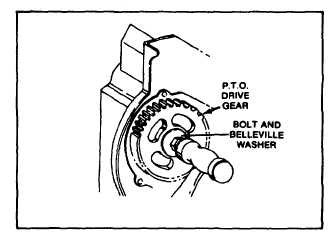

Remove short bolt and Belleville washer from P.T.O.

drive gear, Fig. 5. Loosen long bolt and Belleville washer

two (2) turns on magneto side and tap head of bolt with

hammer to loosen cam gear shaft. Turn bolt out while

pushing out cam gear shaft. Remove bolts from cam

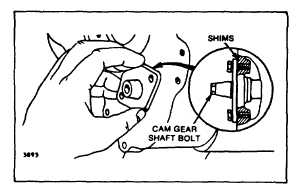

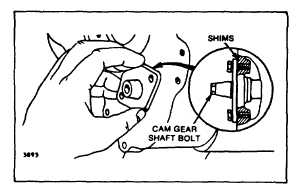

gear bearing, Fig. 6. While holding cam gear, remove

cam gear bearing and remove cam gear, Fig. 7.

Fig. 5. Remove Short Bolt

Fig. 6. Remove Long Bolt

Model Series 301400, 302400, 325400, 326400

Loosen long bolt two (2) turns. Use hammer to drive out

cam gear shaft and cam gear plug. Loosen bolt while

pushing out cam gear shaft and plug. Remove bolts and

cam gear bearing, Fig. 6. Remove cam gear, Fig. 7.

Fig. 7 - Removing Cam Gear Bearing

2