CRANKSHAFTS & CAM GEARS

End Play

Aluminum Engines -- Ball Bearing

Proceed as in aluminum plain bearings, except the thrust

washer is added to the magneto end of the crankshaft

instead of the power take-off end. Thrust washer cannot

be used on engines with two (2) ball bearings.

Sump Installation

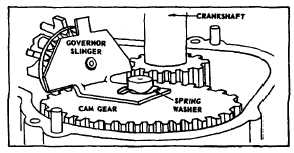

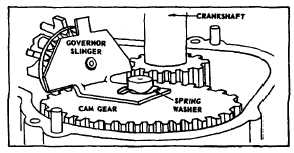

Model 100900 and 130900 Series

On these models use spring washer on cam gear as

shown in Fig. 17.

Fig. 17 Sump Installation –

Model Series 100900 and 130900

To protect the oil seal while assembling the crankcase

cover, put oil or grease on the sealing edge of the oil

seal. Wrap a piece of thin cardboard around the

crankshaft so the seal will slide easily over the shoulder

of crankshaft. If the sharp edge of the oil seal is cut or

bent under, the seal may leak.

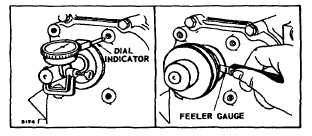

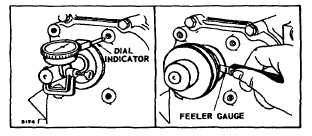

Checking End Play

The end play may be checked by assembling a dial

indicator on the crankshaft with the pointer against the

crankcase. Move the crankshaft in and out. The

indicator will show the end play. Fig. 18. The other

method is to assemble a pulley to the crankshaft and

measure the end play with a feeler gauge. Fig. 18. End

play should be .002.-008" (.05-.20 mm).

Fig. 18. Checking Crankshaft End Play

INSTALL CRANKSHAFT AND CAM GEAR

Cast Iron Engines -- Plain Bearing

Assemble the tappets to the cylinder, then insert the cam

gear. Push the camshaft into the camshaft hole in the

cylinder from the flywheel side through the cam gear.

With a blunt punch, press or hammer the camshaft until

the end is flush with the outside of the cylinder on the

power take-off side. Place a small amount of sealer on

the camshaft plug, then press or hammer it into the

camshaft hole in the cylinder at the flywheel side. Install

crankshaft so timing marks on teeth and cam gear align.

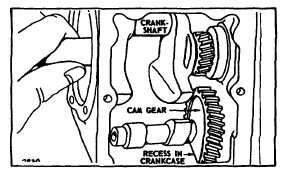

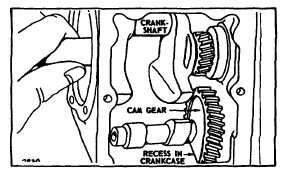

All Cast Iron Engines -- Ball Bearing

Except Models 300000 and 320000

Assemble the tappets, then insert cam gear into the

cylinder, pushing the cam gear forward into the recess in

front of the cylinder. Insert crankshaft into cylinder. Turn

camshaft and crankshaft until timing marks align, then

push cam gear back until it engages the gear on the

crankshaft with timing marks together. Insert camshaft.

Fig. 19. Place a small amount of sealer on the camshaft

plug, then press or hammer it into the camshaft hole in

the cylinder at the flywheel side.

Fig. 19. Install Crankshaft

Cast Iron Engines -- End Play

Plain Bearing and Ball Bearing

The crankshaft end play should be .002" (.05 mm) to

.008" (.20 mm) with one .015" (.38 mm) gasket in place.

If the end play is less than .002" (.05 mm), additional

gaskets of .005" (.13 mm) or .009" (.23 mm) may be

added to the .015" (.38 mm) gasket in various

combinations to attain proper end play. If the end play is

more than .008" (.20 mm) with one .015" (.38 mm)

gasket in place, a .009" (.23 mm) or .005" (.13 mm)

gasket may be used. Fig. 20.

7