TM 5-4240-501-14P

CRANKSHAFTS & CAM GEARS

Auxiliary Drive with Clutch

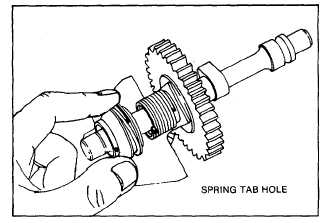

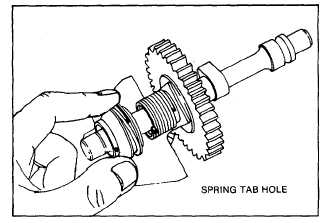

Fig. 36. - Install Clutch Sleeve

Slide thin thrust washer and worm on cam gear. Slide in

thick thrust washer. Slide on copper washer with gray

coated side toward thrust washer. Install "E" ring and

check worm gear end play as described in "Check Cam

Gear" section, page 10.

Inspect cam gear assembly as outlined in "Inspect Clutch

Operation" section, page 10.

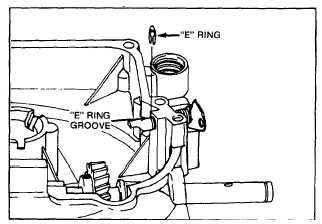

REMOVE CONTROL LEVER SHAFT

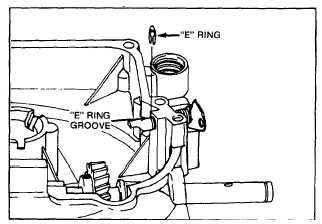

Remove "E" ring, Fig. 37. Slide control lever and shaft

out slowly until lever clears boss on sump. Slowly

release spring tension and then remove shaft, spring and

"O" ring seal.

Inspect shaft assembly for loose lever, worn or broken

parts. Replace as needed.

Fig. 37. - Remove "E" Ring

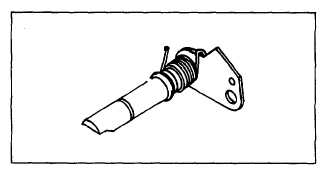

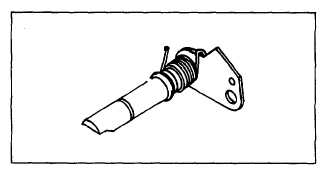

ASSEMBLE CONTROL LEVER AND

SHAFT ASSEMBLY

Install return spring on shaft and lever assembly as

shown in Fig. 38. Then install "O" ring seal on shaft.

Lubricate "O" ring and shaft lightly with engine oil.

Fig. 38. - Assemble Spring

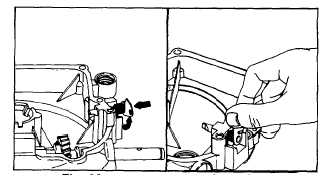

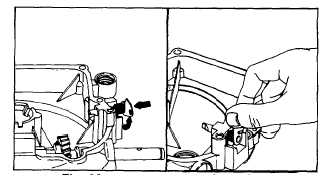

Slide control lever assembly into shaft bore, Fig. 39, as

far as it will go. Rotate lever clockwise to put tension on

return spring. When lever clears stop boss, push lever

and spring in until lever stops. Install "E" ring. Leg of

spring may need to be pushed against sump, Fig. 40.

Lever Installation Spring Installation

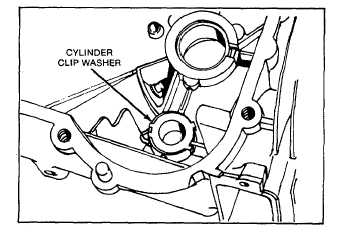

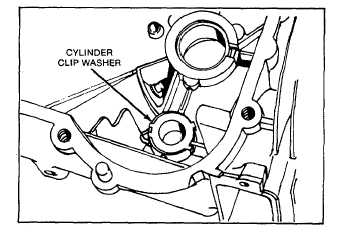

CYLINDER CLIP WASHER

Should clip washer in cylinder require replacing, be sure

flat on clip washer is in line with flat on cam bearing boss

and spring tabs are on both sides of cam bearing web,

Fig. 41.

Fig. 41.—Cylinder Clip Washer

12

Fig. 39.

Fig. 40.