CYLINDERS

Resizing Bore

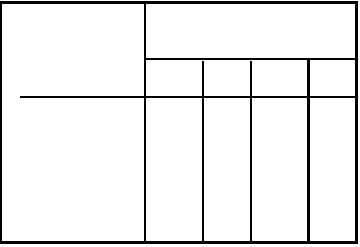

TABLE NO. 1 (Cont’d.)

BASIC ENGINE MODEL

STANDARD BORE SIZE

OR SERIES

DIAMETER

MAX

MIN.

ALUMINUM CYLINDER

Milli-

Milli-

‘

Inches

Meter

Inches

Meter

5, 5S, 6, N

2.0000

50.80

1.9990

50.77

8

2.2500

57.15

2.2490

57.12

9

2.2500

57.15

2.2490

57.12

14

2.6250

66.68

2.6240

66.65

19, 23, 190000, 200000

3.0000

76.20

2.9990

76.17

230000

3.0000

76.20

2.9990

76.17

240000

3.0625

77.79

3.0615

77.76

300000

3.4375

87.31

3.4365

87.29

320000

3.5625

90.49

3.5615

90.46

If a boring bar is used, a hone must be used after the

boring operation to produce the proper cylinder wall

finish.

Honing can be done with a portable electric drill, but it is

easier to use a drill press.

To Set Up For Honing

Clean cylinder at top and bottom to remove burrs and

pieces of base and head gaskets.

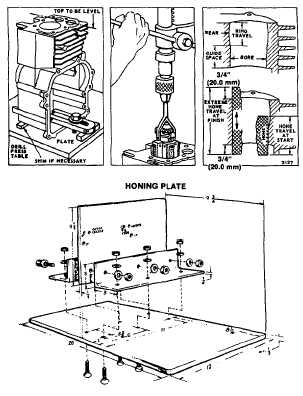

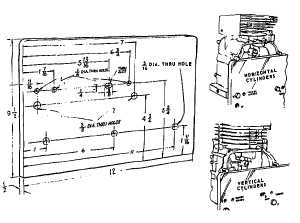

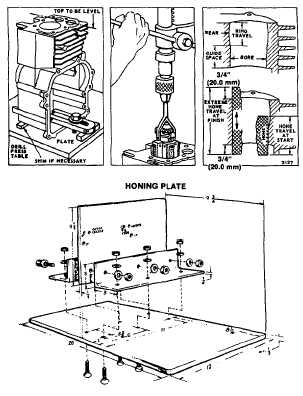

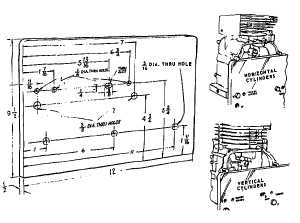

Fig. 2 - Honing Cylinder

(See page 8 for enlarged drawing.)

Fasten cylinder to a heavy iron bracket or use honing

plate. Fig. 2. Some cylinders require shims. Use a

level to align drill press spindle with bore.

Oil surface of drill press table liberally. Set plate and

cylinder on drill press table. (Do not anchor to drill press

table.) If using portable drill, set plate and cylinder on

floor. Place hone drive shaft in chuck of drill or portable

drill.

Slip hone into cylinder; Fig. 2, Illus. 2. Connect drive

shaft to hone and set stop on drill press so hone can only

extend 3/4" (20.0 mm) to 1" (25.0 mm) from top or

bottom of cylinder. If using a portable drill, cut a wood

block to place inside of cylinder as a stop for home.