TM 5-4240-501-14P

CYLINDERS

Ball Bearing

On cast iron cylinders, change from rough stone to

finishing stone when within .0015" (.04 mm) of desired

size, then use finishing stones. ALWAYS HONE .010"

(.25 mm) or .020" (.51 mm), or .030" (.76 mm) ABOVE

THE STANDARD DIMENSIONS GIVEN IN TABLE NO.

1.

CYLINDER FINISH AND CLEANING

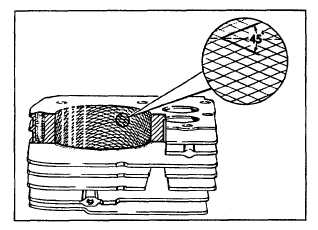

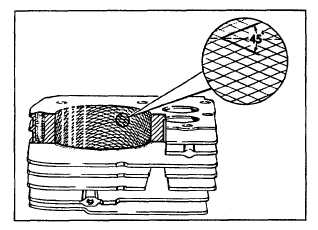

The finish resized cylinder should have a cross-hatch

appearance, Fig. 3. Proper stones, lubrication and

spindle speed along with rapid movement of hone within

the cylinder during the last few strokes, will produce this

finish. Cross-hatching will allow proper lubrication and

rino break-in.

Fig. 3 - Cross Hatch

IT

IS

MOST

IMPORTANT

THAT

THE

ENTIRE

CYLINDER BE THOROUGHLY CLEANED AFTER

HONING. WASH THE CYLINDER CAREFULLY IN A

SOLVENT SUCH AS KEROSENE OR COMMERCIAL

SOLVENT. THE CYLINDER BORE SHOULD THEN BE

CLEANED WITH A BRUSH, SOAP AND HOT WATER.

BEARINGS

BALL BEARING

To check a ball bearing, rotate the bearing slowly by

hand: if any roughness is noted, bearing should be

replaced.

Wash bearing in a clean solvent. Re-oil with engine oil

during assembly.

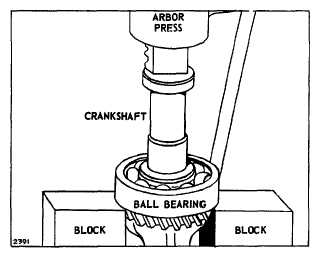

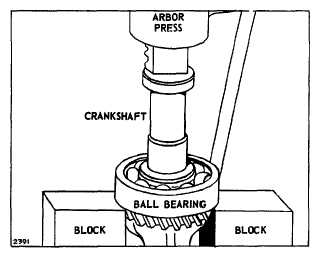

Ball bearings are a press fit on the crankshaft. If bearing

is to be replaced, it should be removed in an arbor press.

Fig. 4. (bearing should not be reused if removed from

crankshaft.)

NOTE: Bearing shield faces crankshaft crank pin.

Fig. 4 - Removing Ball Bearings

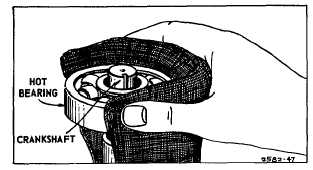

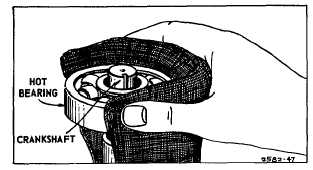

To install, heat bearing in hot (2500 F Max.) (1200 C

Max.) oil. Place crankshaft in a vise with bearing side

up. When bearing is hot it will be a slip fit on crankshaft

journal. Grasp bearing with the shield down and slide it

on the crankshaft. Fig. 5. The bearing will tighten while

cooling. Do not quench.

Fig. 5 - Install Ball Bearings

PLAIN BEARINGS

Checking

Bearings should be replaced if scored or if plug gauge

will enter. Try gauge at several locations in bearing. Fig.

6. See gauge listing in Table No. 3.

3