CRANKSHAFTS & CAM GEARS

Auxiliary Drive with Clutch

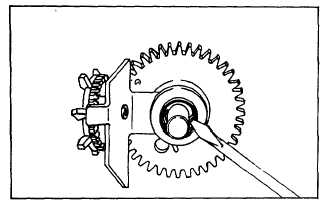

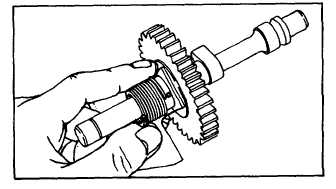

Fig. 32. - Check Cam Gear

CAM GEAR DISASSEMBLY -

EARLY DESIGN

Remove "E" ring retainer. Slide off copper washer, thick

thrust washer, worm and thin thrust washer. Cam gear,

oil slinger, clutch sleeve and springs are serviced with a

current production assembly.

INSPECT PARTS

Inspect for worn, burred or broken parts and replace as

required.

ASSEMBLE CAM GEAR -

EARLY DESIGN

Slide worm gear with thin thrust washer on cam gear.

Slide on thick thrust washer. Slide on copper colored

washer with gray coated side toward thick thrust washer.

Install "E" ring retainer and check worm end play as

described in "Check Cam Gear" section above. Inspect

cam gear assembly as outlined in "Inspect Clutch

Operation" section above.

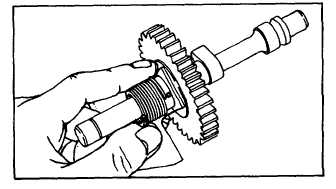

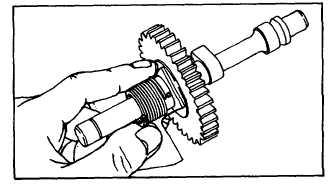

DISASSEMBLY CAM GEAR -

CURRENT DESIGN

Remove "E" ring. Slide off thrust washers and worm

gear. Use thin blade screwdriver or similar tool to pry

lower clutch spring tab out of hole in clutch sleeve, Fig.

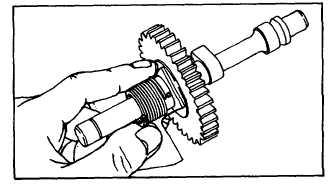

33. Remove clutch sleeve. Slide clutch spring down,

Fig. 34 and lift out upper spring tab to remove spring.

Cam gear, oil slinger and clutch drive hub are serviced

as an assembly.

Fig. 33. - Remove Clutch Sleeve

Fig. 34. - Remove Clutch Spring

INSPECT PARTS

Inspect for worn, broken or burred parts. Replace as

required.

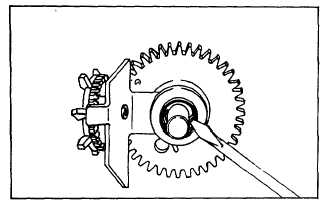

ASSEMBLE CAM GEAR - CURRENT DESIGN

Assemble clutch spring as shown in Fig. 35. Align E

hole in clutch sleeve with tab or spring and slide on.

Depress spring tab,’ if required. When clutch sleeve is in

place, spring tab should be in sleeve hole, Fig. 36.

Fig. 35. - Assemble Clutch Spring

11