CRANKSHAFTS & CAM GEARS

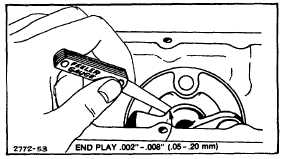

End Play

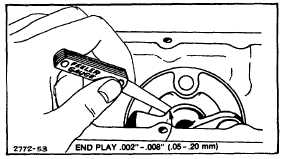

Fig. 20. Checking Crankshaft End Play

If the end play is more than .008" (.20 mm) with one

.015" (.38 mm) gasket in place, a .009" (.23 mm) or .005"

(.13 mm) gasket may be used. Fig. 20.

If the end play is more than .008" (.20 mm) with one

.005" (.13 mm) gasket in place, a thrust washer is

available and is placed on the crankshaft power take-off

end. Fig. 20.

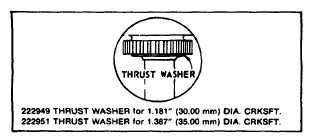

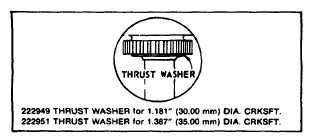

222949 Thrust Washer for 1.181" (30 mm) diameter

crankshaft.

222951 Thrust Washer for 1.378" (35 mm) diameter

crankshaft.

NOTE: Thrust washer cannot be used on ball bearing

engines.

Checking End Play

On models with a removable base, the end play can be

checked with a feeler gauge between the crankshaft

thrust face and the bearing support on plain bearing

engines. Fig. 20.

Fig. 21. Correcting Crankshaft End Play

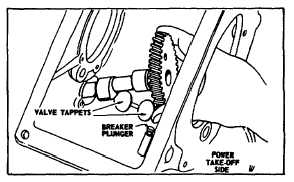

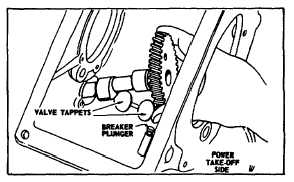

SERVICE PROCEDURE FOR

ENGINE MODEL SERIES 300400 and

320400

Install breaker plunger and tappets, then insert cam gear

from power take-off side of cylinder. See Fig. 22.

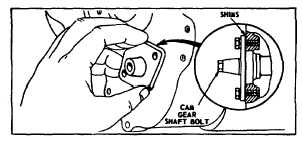

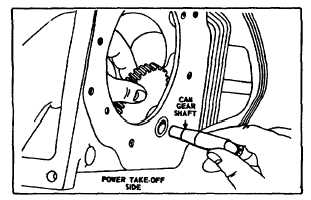

Fig. 22. Inserting Cam Gear

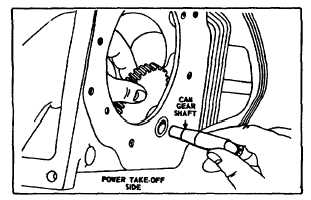

Slide cam gear shaft through power take-off bearing and

into cam gear. See Fig. 23.

Fig. 23. Sliding Cam Gear Shaft

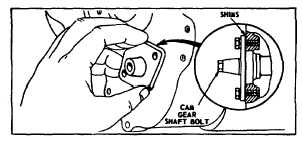

Insert magneto side cam gear bearing on cylinder.

Torque cam gear bearing screws to 85 inch pounds (1.0

mkp, 9.6 N•m). Install long cam gear shaft bolt (5-1/2")

(14 cm) to prevent loss of shaft. See Fig. 24.

Fig. 24. Inserting Cam Gear

CHECKING AND CORRECTING

CAM GEAR END PLAY

Cam gear end play tolerance is machined at the factory

and normally requires no adjustment, unless the

magneto side cam gear bearing or cam gear is replaced.

8