CRANKSHAFTS & CAM GEARS

Checking

CHECKING CAM GEAR

All Engines

Inspect gear teeth for wear and nicks. Cam shaft and

cam gear journals and lobe rejection sizes are shown in

Table No. 2.

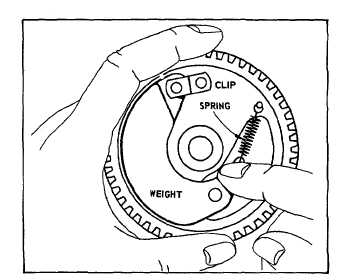

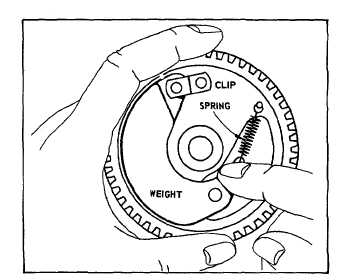

Check automatic spark advance on models equipped

with "Magna-Matic." Fig. 9. Place cam gear in normal

operating position with the movable weight down. Press

the weight down. Release. The spring should lift the

weight. If not, the spring is stretched or the weight is

binding. Repair or replace.

Fig. 9. Checking Automatic Spark Advance

TABLE NO. 2

CAM GEAR REJECT SIZES

MODEL SERIES

CAM GEAR OR SHAFT JOURNAL

CAM LOBE

ALUMINUM CYLINDER

Inches

Millimeter

Inches

Millimeter

6B, 60000

.498

12.65

.883

22.43

8B, 80000*

.498

12.65

.883

22.43

82000, 92000, 94000

.498

12.65

.883

22.43

110900, 111200, 111900

.436 Mag.

.498 PTO

11.07 Mag.

12.65 PTO

.870

22.10

100000, 130000

.498

12.65

.950

24.13

140000, 170000, 190000

.498

12.65

.977

24.82

220000, 250000

.498

12.65

1.184

30.07

CAST IRON CYLINDER

Inches

Millimeter

Inches

Millimeter

5, 6, 8, N

.372

9.45

.875

22.23

9

.372

9.45

1.124

28.55

14, 19, 190000

.497

12.62

1.115

28.32

200000

.497

12.62

1.115

28.32

23, 230000

.497

12.62

1.184

30.07

240000

.497

12.62

1.184

30.07

300000

#

#

1.184

30.07

320000

#

#

1.215

30.86

*Auxiliary Drive Models P.T.O. -- .751 in. (19.08 mm)

#Magneto Side -- .8105 in. (20.59 mm)

P.T.O. -- .6145 in. (15.61 mm)

4