CRANKSHAFTS & CAM GEARS

Installing

INSTALL CRANKSHAFT AND CAM GEAR

Aluminum Alloy Engines - Plain Bearing

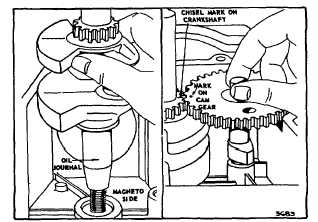

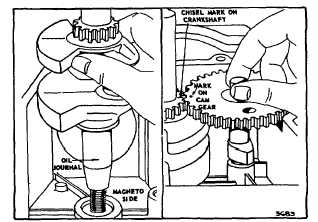

In aluminum alloy models the tappets are inserted first,

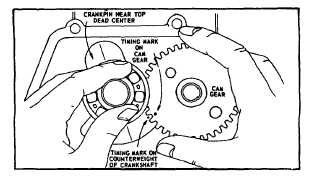

the crankshaft next, and then the cam gear. When

inserting the cam gear, turn the crankshaft and cam gear

so that the timing marks on the gears align. Fig. 14.

NOTE: Model series 94000, 171700, 191700, 251700,

and 252700 have a removable timing gear. When

installing timing gear, have inner chamfer toward

crankpin. This assures that timing mark will be visible.

Fig. 14. Aligning Timing Marks

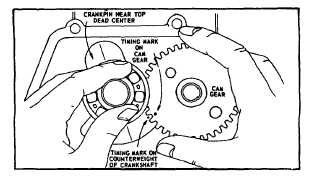

Aluminum Alloy Engines Ball Bearing

On crankshafts with ball bearings, the gear teeth are not

visible for alignment of the timing marks, therefore, the

timing mark is on the counterweight. Fig. 15. On ball

bearing equipped models the tappets are installed first.

The crankshaft and cam gear must be inserted together;

align timing marks as shown in Fig. 15, and insert

crankshaft and cam gear.

Fig. 15. Ball Bearing Engines

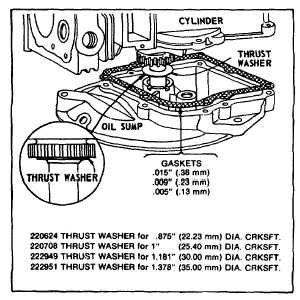

CRANKCASE COVER and

CRANKSHAFT END PLAY

All Models

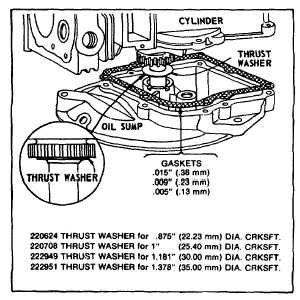

The crankshaft end play on all models, plain and ball

bearing, should be .002" (.05 mm) to .008" (.20 mm).

The method of obtaining the correct end play varies,

however, between cast iron, aluminum, plain and ball

bearing models. New gasket sets include three

crankcase cover or bearing support gaskets -- .005" (.13

mm), .009" (.23 mm) and .015" (.38 mm).

Aluminum Engines Plain Bearing

The end play should be .002" (.05 mm) to .008" (.20 mm)

with one .015" (.38 mm) gasket in place. If the end play

is less than .002" (.05 mm), which would be the case if a

new crankcase or sump cover is used, additional

gaskets of .005" (.13 mm), .009" (.23 mm) or .015" (.38

mm) may be added in various combinations to attain the

proper end play.

If the end play is more than .008" (.20 mm) with one

.015" (.38 mm) gasket in place, a thrust washer is

available and to be placed on the crankshaft power take-

off end, between the gear and crankcase cover or sump.

Additional gaskets .005" (.13 mm) or .009" (.23 mm) will

then have to be added to the .015" (.38 mm) gasket for

proper end play. NOTE: On aluminum models never

use less than .015" (.38 mm) gasket. Fig. 16.

Fig. 16. Correcting Crankshaft End Play

6