CRANKSHAFTS & CAM GEARS

Auxiliary Drive with Clutch

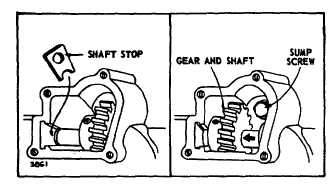

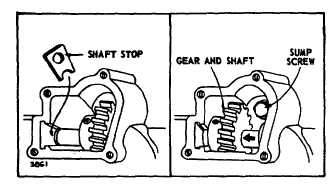

Fig. 28. Auxiliary P.T.O.

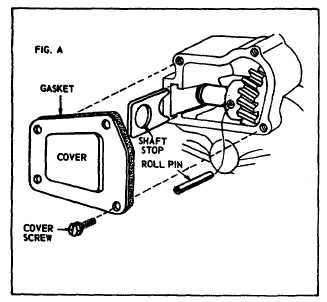

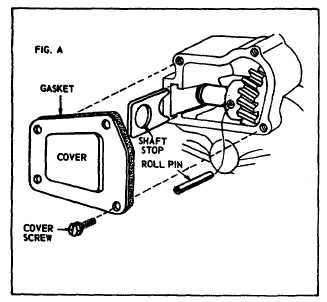

When installing cover, Fig. 29, put non-hardening sealant

on cover screws.

Fig. 29. Installing Cover

AUXILIARY P.T.O. -- With Clutch –

Model Series 110980

This auxiliary power take-off shaft is perpendicular to the

crankshaft. It rotates at the rate of one revolution for

every 8-1/2 revolutions of the crankshaft. Rotation of the

shaft is controlled by a clutch on the cam gear. The

clutch is engaged or disengaged by a control lever

mounted on the oil sump.

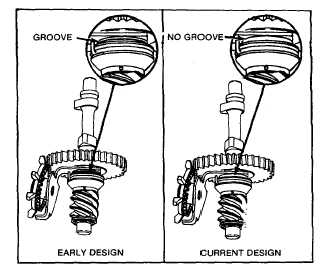

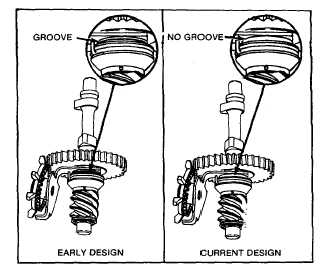

Early production cam gears, Fig. 30, are serviced as an

assembly consisting of cam gear oil slinger, clutch hub,

clutch spring and clutch sleeve assembly. Later

production cam gears are serviced as individual parts

except for the cam gear which consists of cam gear, oil

slinger and clutch hub.

Fig. 30. Cam Gear and Clutch

To remove sump: Sump is held on by six screws. Five

screws are exposed. The sixth screw is under the

auxiliary drive cover, Fig. 28. Remove cover and lift out

shaft stop, Fig. 28. Slide driveshaft and gear over to

expose head of cap screw. Cap screw can be removed

with 7/16" socket.

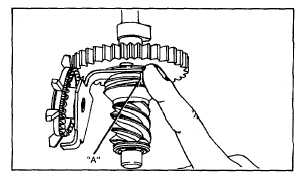

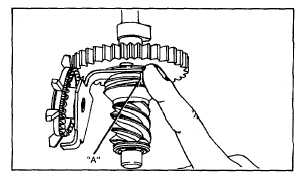

INSPECT CLUTCH OPERATION

Push on spring tang, "A," Fig. 31, turning spring and

clutch sleeve in a counterclockwise direction. Spring and

sleeve should rotate approximately 1/8" turn. Worm gear

should not rotate in the same direction. With clutch

released, worm gear should rotate freely in both

directions.

Fig. 31. Inspect Clutch

CHECK CAM GEAR

Check worm gear end play using feeler gauges at point

"A," Fig. 32. End play should not be less than .004" (.10

mm) or more than .017" (.43mm).

10