CYLINDERS

Inspection & Resizing Bore

Section 11

CYLINDERS & BEARINGS

INSPECTION

All Models

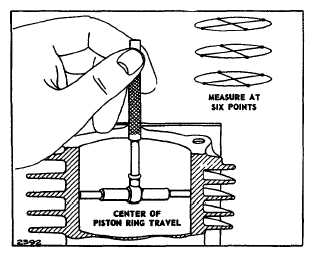

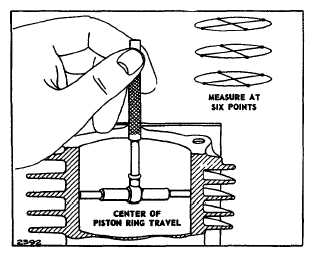

Always inspect the cylinder after the engine has been

disassembled. Visual inspection will show if there are

any cracks, stripped bolt holes, broken fins or if the

cylinder wall is damaged. Use a telescoping gauge and

dial indicator or inside micrometer to determine the size

of the cylinder bore. Measure at right angles. See Fig.

1. Table No. 1 lists the standard cylinder bore sizes.

If the cylinder bore is more than .003" (.08 mm) oversize,

or .0015" (.04 mm) out of round on cast iron cylinders, or

.0025" (.06 mm) out of round on lightweight cylinders, it

must be resized.

Fig. 1 - Check Cylinder Bore

NOTE: Do not deglaze cylinder walls when installing

piston rings in aluminum cylinder engines.

NOTE: Chrome ring sets are available for most models.

See Bulletin #479 or Illustrated Parts List. They are used

to control oil consumption in bores worn to .005" (.13

mm) over standard and do not require honing or glaze

breaking the bore to seat.

RESIZING

Resize Cylinder Bore to Next Oversize

All Models

ALWAYS RESIZE TO EXACTLY .010" (.25 mm) or .020"

(.51 mm), or .030" (.76 mm) OVER STANDARD SIZE

AS SHOWN IN TABLE NO. 1. IF THIS IS DONE

ACCURATELY, THE STOCK OVERSIZE RINGS AND

PISTONS WILL FIT PERFECTLY AND PROPER

CLEARANCES WILL BE MAINTAINED. Cylinders,

either cast iron or aluminum, can be quickly resized with

a good hone such as Briggs & Stratton part #19205 for

aluminum cylinders or part #19211 for cast iron

cylinders. Contact your Briggs & Stratton source of

supply. Use the stones and lubrication recommended by

the hone manufacturers for the various engine models,

to produce the correct cylinder wall finish.

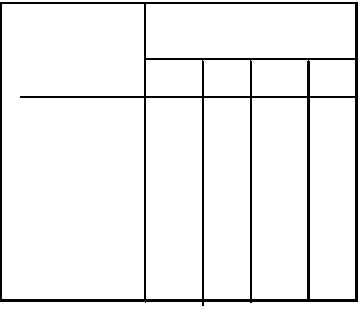

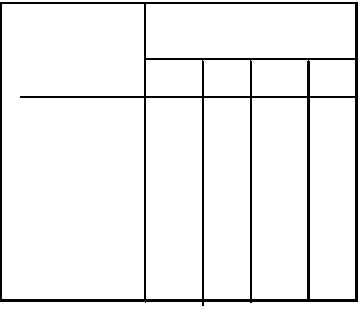

TABLE NO. 1

BASIC ENGINE MODEL

STANDARD BORE SIZE

OR SERIES

DIAMETER

MAX

MIN.

ALUMINUM CYLINDER

Milli-

Milli-

‘

Inches

Meter

Inches

Meter

B, 60000 before

2.3125

58.74

2.3115

58.71

Ser #5810060

60000 after

2.3750

60.33

2.3740

60.30

Ser #5810030

8B, 80000 82000

2.3750

60.33

2.3740

60.30

92000, 93000, 94000

2.5625

65.09

2.5615

65.06

100000

2.5000

63.50

2.4990

63.47

110000

2.7812

70.64

2.7802

70.62

130000

2.5625

65.09

2.5615

65.06

140000

2.7500

69.85

2.7490

69.82

170000, 190000

3.0000

76.20

2.9990

76.17

220000, 250000

3.4375

87.31

3.4365

87.29

(Table No.1 - Cast Iron Cylinders continued on page 2.)

JUNE 1981