CRANKSHAFTS & CAM GEARS

Auxiliary Drive

Cam gear end play is checked in the same manner as

crankshaft end play.

Cam shaft end play must be .002" (.05 mm) to .008" (.20

mm). If end play is less than .002" (.05 mm), add service

shims (#270516-.009" (.23 mm); #270517-.007" (.18

mm); or #270518-.005" (.13 mm) to obtain proper end

play. If end play is more than .008" (.20 mm), use

service bearing assembly kit #299706, which includes

above shims to obtain proper end play.

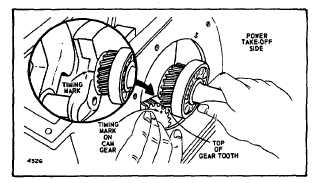

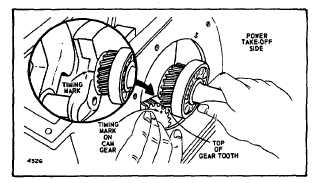

Use chalk or crayon to mark the top of crankshaft gear

tooth, whose inner end is directly in line with the notch of

the timing mark. See Fig. 25.

Fig. 25. Aligning Timing Marks

Align timing marks on crankshaft and cam gear, and

install crankshaft. Install crankshaft carefully so crankpin

is not damaged.

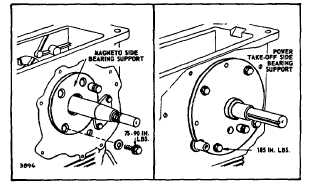

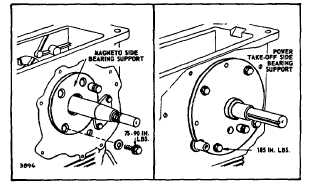

Install power take-off and

magneto

side

bearing

supports. Torque power take-off support screws to 185

inch-pounds (2.2 mkp, 20.9 N•m). Torque magneto side

support screw to 85 inch-pounds (1.0 mkp, 9.6 N•m).

See Fig. 26.

Fig. 26. Installing Bearing Supports

See Section 12 for timing of synchro-balance timing

gears.

CHECKING AND CORRECTING

CRANKSHAFT END PLAY

Crankshaft end play tolerance is machined at the factory

and normally requires no adjustment, unless the bearing

supports or crankshaft is replaced.

Crankshaft end play must be .002" (.05 mm) to .008" (.20

mm). If end play is less than .002" (.05 mm), add service

shims (#270513-.015" (.38 mm); #270514-.010" (.25

mm); or #270515-.005" (.13 mm) to obtain proper end

play. If end play is more than .008" (.20 mm), use

service bearing support assembly kit #299705, which

includes the above shims, to obtain proper end play.

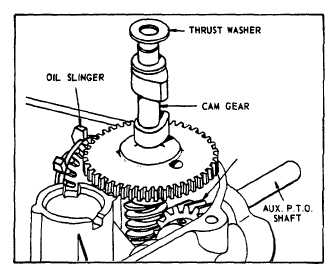

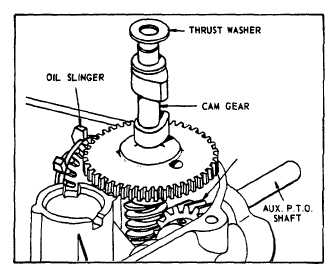

Auxiliary P.T.O. -- Model Series 92580,

92980, 94580, 94980, 110980, 111980

This auxiliary power take-off shaft is perpendicular to the

crankshaft. It rotates at the rate of one revolution for

every 81/2 revolutions of the crankshaft. On these

models, the cam gear, worm gear and oil slinger are a

Factory assembly and are not available as separate

pieces. See Fig. 27.

Fig. 27. Remove and Install Sump Screw

NOTE: If rotation is counterclockwise, the thrust washer

is placed next to the worm gear on camshaft.

To remove the sump: One of the six sump mounting

screws is located under the auxiliary drive cover.

Remove the cover. Lift out shaft stop. See Fig. 28.

Slide gear and shaft sideways to expose head of sump

mounting screw. Use 7/16" socket to remove screw.

9