TM 5-4240-501-14P

CYLINDERS

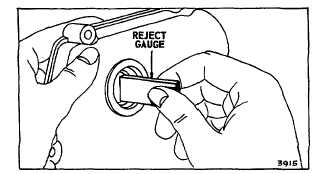

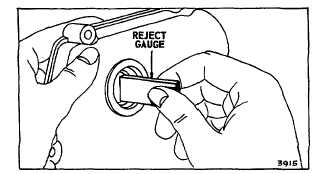

Plain Bearing

Fig. 6 - Checking Bearing

REPLACING PLAIN BEARINGS

Models 9, 14, 19, 20 and 23 Series The crankcase cover

or bearing support should be replaced if the bearing is

worn or scored. Select the correct assembly part

number by referring to the Parts List covering the engine.

Refer to Table No. 3 for main bearing gauges.

TABLE NO. 2

CYLINDER BEARING REJECT SIZE CHART

BASIC ENGINE MODEL

PTO

BEARING

OR SERIES

BEARING

MAGNETO

MAX

MIN.

ALUMINUM CYLINDER

Milli-

Milli-

‘

Inches

Meter

Inches

Meter

6B, 8B*

878

22.30

878

22.30

60000, 80000*

878

22.30

878

22.30

82000, 92000*, 94000*

878

22.30

878

22.30

110900*, 111900*

878

22.30

878

22.30

100000.130000

1.003

25.48

878

22.30

140000, 170000

1.185

30.10

1.004#

5.50#

190000

1.185

30.10

1.004#

25.50#

220000 Horiz

Ball

Ball

Ball

Ball

220000 Vert, 250000

1.383

35.13

1.383

35.13

ALUMINUM CYLINDER

Milli-

Milli-

‘

Inches

Meter

Inches

Meter

5, 6, 8, N

878,

22.30

878

22.30

9

988

25,09

988

25.09

14

1.185

30.10

1.185

30.10

19, 190000, 200000

1.185

30.10

1.185

30.10

23, 230000+

1.382

35.10

1.382

35.10

240000, 300000

Ball

Ball

Ball

Ball

320000

Ball

Ball

Ball

Ball

+Gear Reduction PTO—185" (30.10 mm)

*Auxiliary drive models PTO Bearing Reject size 1.003"

(25.48 mm)

#Synchro-Balanced Magneto Bearing Reject size 1.185"

(30.10 mm)

REPLACING MAGNETO BEARING

Aluminum Cylinder Engines

Except 171700, 191700

There is no removable bearing in these models; the

cylinder must be reamed out so a replacement bushing

can be installed. Place pilot guide bushing in the sump

bearing, with flange of pilot guide bushing toward inside

of sump.

Assemble sump on cylinder. Be careful that pilot guide

bushing does not fall out of place. Place reamer guide

bushing into the oil seal recess in the cylinder. The

reamer guide bushing, along with the pilot guide bushing,

will center the counterbore reamer with the opposite

bearing even though old bearing might be badly worn.

Place counterbore reamer on pilot and insert into cylinder

until the tip of the pilot enters the pilot guide bushing in

the sump. Fig. 7.

Fig. 7 - Counterbore Reaming

Turn reamer clockwise with a steady even pressure until

it is completely through the bearing. Lubricate reamer

with kerosene or Stoddard Solvent.

NOTE: Counterbore reaming may be undertaken without

any lubricant. However, as aluminum material builds up

on reamer flutes, eventual damage to the reamer and

oversize counterbores will be experienced.

Remove sump and pull reamer out without backing it

through the bearing. Clean out reaming chips. Remove

reamer guide bushing from oil seal recess.

Hold new bushing, with notch toward cylinder and in line

with notch on inside of cylinder, (Fig. 8, insert), against

reamed out bearing. Note position of split in bushing.

At a point opposite to the split in the bushing, using a

chisel or screwdriver and hammer, make a notch in the

reamed out cylinder bearing at a 450 angle. Fig. 8.