CYLINDERS

Checking Cam Gear Bearing

REPLACING PTO BEARING

Aluminum Cylinder Engines

The sump or crankcase cover bearing can be repaired in

the same manner as the magneto bearing. However,

one bearing should be completely repaired before

starting the other bearing. After the bearings are

finished, press in the new oil seals.

NOTE: Model 8B-HA, 80590, 81590, 82590,

80790, 81790, 82990, 92590, 92990,

110990, 111990.

The magneto bearing can be replaced as

above; if the sump bearing is worn, the

sump must be replaced. No tools are

available for replacing the sump bearing.

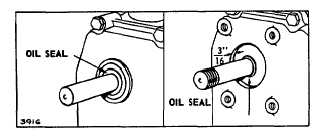

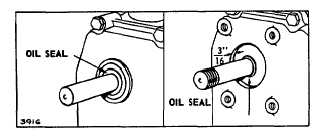

REPLACING OIL SEAL

The oil seal is assembled with the sharp edge of the

leather or rubber toward the inside of the engine.

Lubricate inside diameter of oil seals with "Lubriplate," or

equivalent, before assembling engines.

Most oil seals are pressed in, flush with the hub.

However, models 60000, 80000, 100000 and 130000

using a ball bearing with mounting flange have the seal

pressed 3/16" below crankcase mounting flange. Fig.

13.

Fig. 13 - Replacing Oil Seal

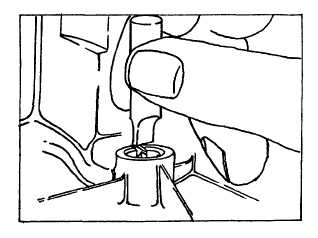

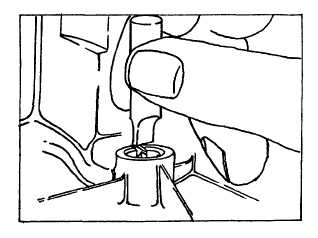

CHECKING CAM GEAR BEARINGS

Check cam gear bushing using 19164 plug gauge as

shown, Fig. 14. If 1/4" or more of’ gauge enters bearing

bore, bearing is worn beyond reject and the cylinder,

sump or crankcase cover must be replaced.

NOTE: On Model Series 111200, 111900, plug gauge

19164 is used on the sump or crankcase cover cam gear

bearing bore. Reject size of the cylinder cam bearing is

.443 or larger.

Fig. 14 - Checking Cam Gear Bearing

7