TM 5-4240-501-14P

SYNCHRO-BALANCE

Oscillating Counterbalance

Remove counterweight from the shaft.

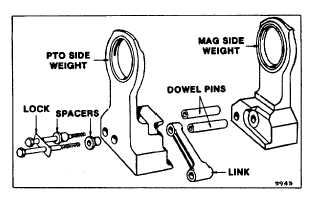

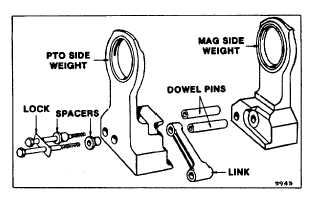

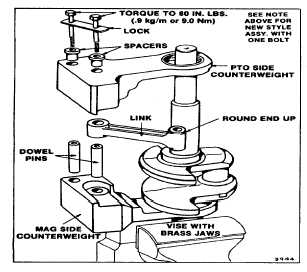

Fig. 9 - Disassembling Counterweight

ASSEMBLY

Assemble magneto side of counterweight to the magneto

side of the crankshaft. Hold the crankshaft and

counterweight in an upright position in a vise. Install both

dowel pins. Slip link over dowel pin with rounded edge of

free end up. Fig. 10.

NOTE: New style counterweight assemblies use only

one (1) dowel pin, one (1) spacer, and one (1) bolt. No

lock is required. Torque to 115 in/lbs. (1.32 mkp or 13.0

Nm).

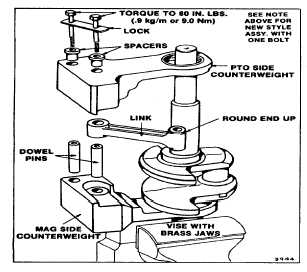

Fig. 10 - Assembling Counterweight to Crankshaft

Slip PTO counterweight in place, aligning counterweight

bearing to the eccentric of crankshaft and against

magneto half of counterweight. Install spacers and

torque bolts to 80 inch-pounds (.9 mkp or 9.0 Nm). Bend

up bolt locks and install crankshaft gear (and key on

MODEL SERIES 171700). Gear is a slip fit - if tight, it

may be heated to expand by laying it on a light bulb.

NOTE: Chamfer on inside diameter of gear must face

shoulder of crankshaft.

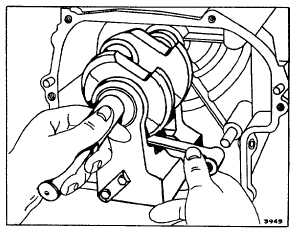

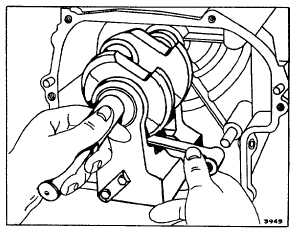

Lay cylinder on its side with cylinder head to the left.

Start magneto journal of crankshaft into the magneto

bearing in the cylinder. Align the link with the crankcase

link

pin

and

push

crankshaft

and

counterweight

assembly into place. Fig. 11.

Fig. 11 - Installing Crankshaft and Counterweight

Assembly

Install connecting rod and piston with lubrication hole in

rod toward magneto side. This will expose rod assembly

marks to view. Assemble the cap screws and screw

locks with dipper toward cam gear side. Torque screws

and bend up locks. Proceed to install tappets. cam

gear. etc.. in usual manner.

Table No. 1

Crankshaft Eccentric Reject Sizes

Basic Model Series

Eccentric

‘

Inch

Milllmeter

171700 & 191700

1.870

47.50

251700 & 252700

2.120

53.85

Counterweight Bearing Reject Sizes

Basic Model Series

Counterweight Bearing.

Inch

Milllmeter

171700 & 191700

1.881

47.78

251700 & 252700

2.131

54.13

4