SYNCHRO-BALANCE

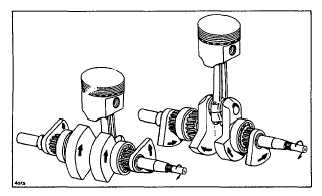

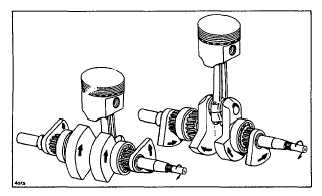

Rotating Counterbalance

Section 12

SYNCHRO-BALANCE

Briggs & Stratton uses two methods of Synchro-

Balancing engines.

One system uses counterweights that are geared to

rotate in a direction opposite from the crankshaft

counterweights. The other system uses a counterweight

that oscillates opposite to the direction of the piston.

Each system performs the same function of substantially

reducing engine vibration, thereby giving exceptionally

smooth engine performance.

Fig. 1 - Cast Iron Engines,

Rotating Counterbalance

ASSEMBLING AND TIMING

ROTATING SYNCHRO-BALANCERS,

CAST IRON ENGINES

Remove all traces of oil or dirt from tapered surfaces of

drive gears and cam shaft before assembling gears to

camshaft. Turn crankshaft until piston is at top dead

center.

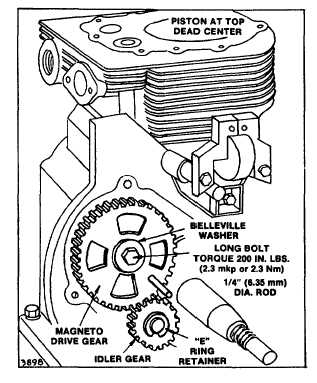

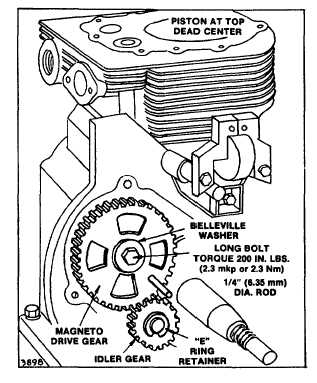

Remove long 5-1/2" (139.7 mm) cam gear shaft bolt,

place magneto drive gear on cam gear taper. Install bolt

with Belleville washer, finger tight. See Fig. 2.

Fig. 2--Installing and Timing

Magneto Drive Gear

On MODEL SERIES 300400 and 320400 only, place

PTO drive gear on the other end of camshaft. Install

short cam gear bolt with Belleville washer, finger tight.

See Fig. 3.

To time drive gears, insert short pieces of 1/4" (6.35 mm)

rod through 1/4" (6.35 mm) holes in drive gears, and into

locating holes in crankshaft bearing support plates. Fig.

2. For MODEL SERIES 300400 and 320400 also see

Fig. 3. With piston at exactly TOP DEAD CENTER,

torque cam gear bolt(s) [with 1/4" (6.35 mm) rods in

place] to 200 inch pounds (2.3 mkp or 22.6 Nm) . Be

certain piston does not move. Remove the 1/4" (6.35

mm) rods.

Install idler gear (s). Install snap-in "E" rings to retain

gears. No timing is necessary. Figs. 2 and 3.

JUNE 1981

1