SYNCHRO-BALANCE

Oscillating Counterbalance

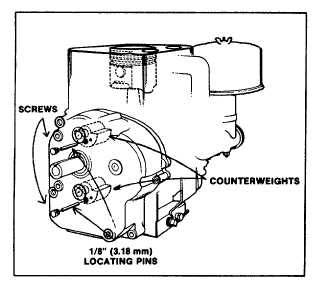

To do so remove two small screws from cover and insert

1/8" (3.18 mm) diameter locating pins through screw

hole and into timing hole provided in counterweights, Fig.

6.

Fig. 6 - Timing Counterbalance Gears

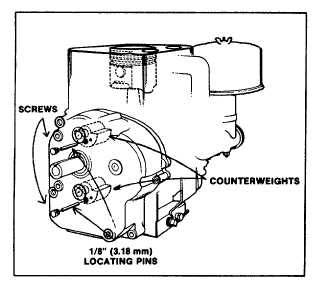

With the piston at TOP DEAD CENTER, install the

crankcase cover assembly and cover gasket. Remove

the locating pins. Coat threads of timing hole screws

with a non-hardening sealant, then install screws and

fibre sealing washers.

If counterweights are removed from crankcase cover,

exercise care in handling or cleaning to prevent losing

needle bearings.

ASSEMBLY OF COUNTERWEIGHTS

Install counterweights on shafts in crankcase cover.

Install counterweight retainers and torque screws to 50

inch pounds (.57 mkp or 5.6 Nm).

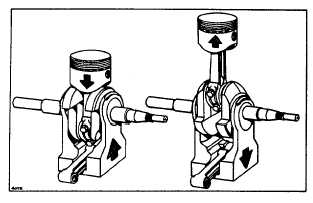

SERVICE PROCEDURES FOR

MODEL SERIES 171700, 191700,

251700 & 252700 OSCILLATING

COUNTERBALANCE SYSTEM

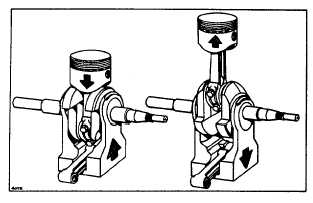

Fig. 7 - Oscillating Counterbalance

Disassembling Oscillating

Counterbalance

Use a screwdriver and hammer to open the connecting

rod cap screw locks - remove connecting rod screws -

remove connecting rod and piston assembly. Remove

crankshaft and counterweight assembly. Remove

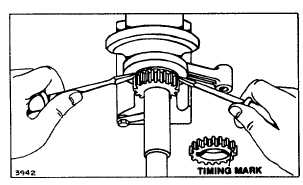

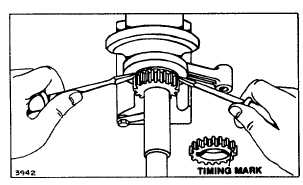

crankshaft gear - in the event it should fit tight, it can be

pried off with two screwdrivers, being careful not to

damage the gear. Fig. 8. Save the key on MODEL

SERIES 171700 only. Key is staked in on MODEL

SERIES 191700, 251700 and 252700.

Fig. 8 - Removing Crankshaft Gear

Disassemble the counterweight. Open the locks and

remove one or two screws holding the halves of the

counterweight together. Separate and remove the dowel

pin. link and spacer. Fig. 9.

3