CYLINDERS

Plain Bearing

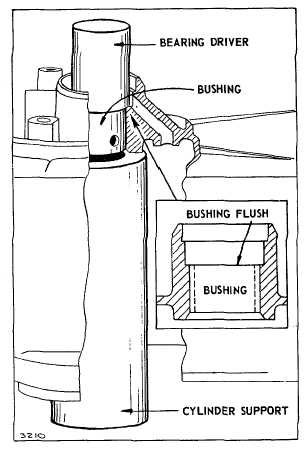

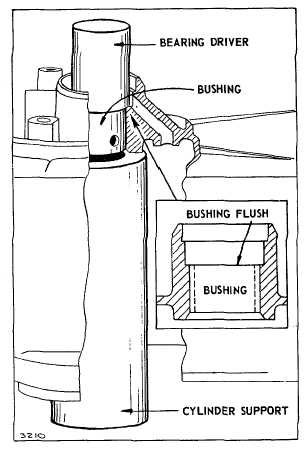

Fig. 9 - Pressing in New Bushing

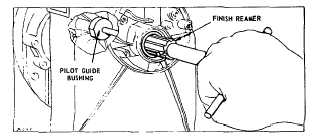

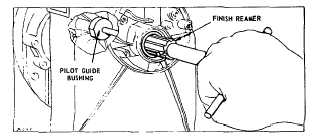

Fig. 10 - Shell Reaming

MAGNETO BEARING

Model Series 171700, 191700

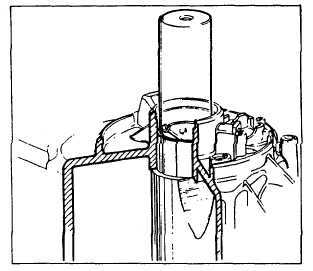

Counterbore ream worn bearing using tools per Table

No. 3 and procedure for standard magneto bushing.

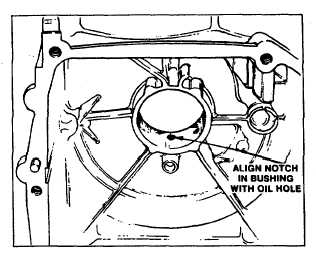

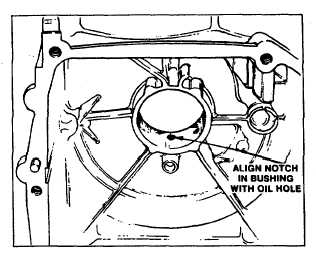

Then place new bushing against reamed out bearing on

inside of cylinder. with bushing notch against cylinder

and in line with oil hole. Fig. 11. Note position of split in

bearing. At a point opposite the split in bushing. use a

chisel or screwdriver and hammer to make a notch in

the. reamed out bearing at a 450 angle.

Fig. 11 - Location of Oil Hole

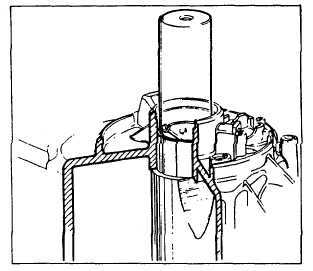

Press in new bushing from outside cylinder, Fig. 12,

using care to keep notch in line with oil hole, Fig. 11,

with bushing driver and cylinder support until bushing is

flush with inside edge of cylinder. Fig. 12. If bushing

notch and bushing oil hole are not aligned, press bushing

through and reinstall.

With a chisel or screwdriver, drive a portion of the

bushing into the notch previously made in cylinder. See

Fig. 11. This is called staking and is done to prevent the

bushing from turning.

Fig. 12 - Pressing in New Bushing

Finish rearm bushing using same procedure for standard

magneto bushing. Clean out breaker point plunger hole

with 19058 finish reamer. Clean out dirt and chips.

6