SYNCHRO-BALANCE

Rotating & Oscillating Counterbalance

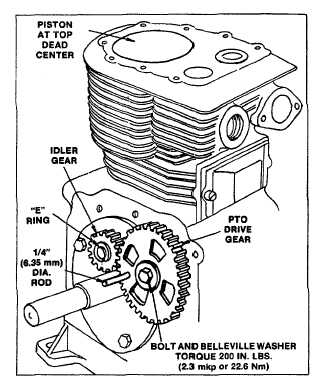

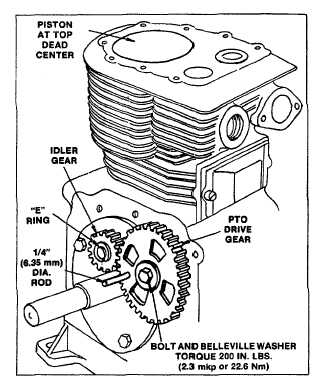

Fig. 3 -- Installing and Timing PTO Drive Gear

The counterweights and ball bearings are an integral part

of the covers, and cannot be removed. Lubricate the ball

bearings and gears with a few drops of engine oil.

PISTON MUST BE AT TOP DEAD CENTER.

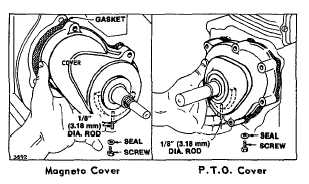

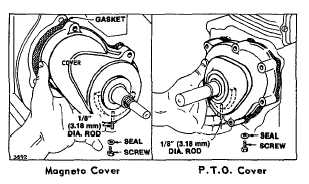

Remove the timing hole screw from cover assembly.

Fig. 4. Insert a short piece of 1/8" (3.18 mm) rod

through timing hole in cover and into maching hole in

counterweight. Fig. 4. The rod holds the counterweight

in the proper position while cover is installed on engine.

Fig. 4 - Removing Timing Hole Screw

Install cover assembly and gasket. using care to avoid

damage to oil seal and making sure that bolt holes line

up with tapped holes in cylinder. To minimize gear

backlash. push magneto side cover toward idler gear

and torque bolts to 120 inch pounds (1.4 mkp or 13.5

Nm). For MODEL SERIES 300400 and 320400 repeat

above for PTO cover, torquing bolts to 200 inch pounds

(2.3 mkp or 22.6 Nm).

Remove timing rods. Coat threads of timing hole screw

with a non-hardening sealant, then install screw and fibre

sealing washer.

MODEL SERIES 251400, 252400 &

253400

These

Model

Series

utilize

two

gear

driven

counterweights in constant mesh with the crankshaft

gear.

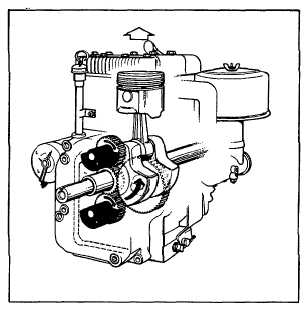

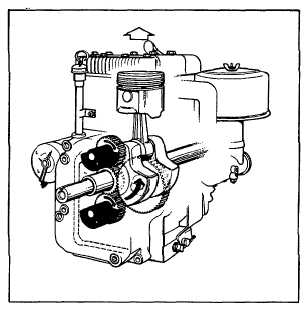

The cut-away view illustrates these gears, mounted in

the crankcase cover, and how the Synchro-Balance

counterweights rotate in opposite direction to crankshaft

rotation, Fig. 5.

Fig. 5 - Aluminum Engines Rotating Counterbalance

System

SERVICE

PROCEDURES

FOR

MODEL

SERIES

251400, 252400 & 253400

The gear driven counterweights must be properly aligned

when cover is installed.

2