TM 9-2350-238-34-2

2-31. MAINTENANCE OF STAGE ONE CARRIER ASSEMBLY.

This task covers:

a. D i s a s s e m b ly

b. Inspection/Repair

c. R e a s s e m b ly

INITIAL SETUP

Tools and Special Tools

Gloves, welder’s

General mechanic’s tool kit, automotive

Helmet, welder’s

(SC 5180-90-CL-N26)

Holder, electrode

Shop equipment, automotive mainte-

Welding, machine, arc

nance and repair: field maintenance,

basic, less power (SC 4910-95-A31)

Materials/Parts

Drill press

Sealing compound (item 18, appx B)

Drill, twist, no. 3

Grinder

References

Press, arbor

MIL-STD-1261C (MR)

Tap and die set

TM 9-2350-238-24P-2

Shop equipment, sets, kits, outfits and

tools: welding shop, trailer mounted

Equipment Conditions

(SC 3431-95-A04)

2-111 Stage one carrier assembly

Apron, welder’s

removed

Electrode, welding

DISASSEMBLY

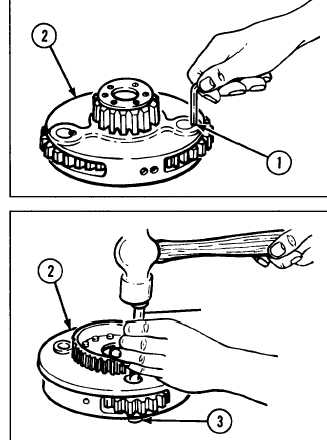

1 Remove three setscrews (1) from carrier

(2).

Mark each of three planet gear

headless straight pins and their loca-

tion in carrier so that planet gear

headless straight pins can be put in

same holes during reassembly.

D R I FT

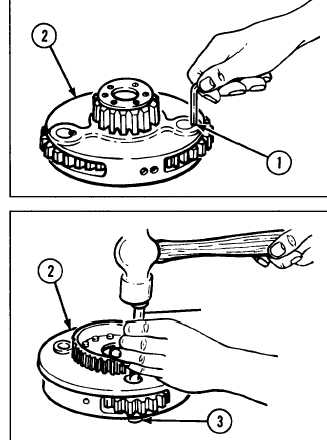

2 Using hammer and drift, remove three

planet gear headless straight pins (3) from

carrier (2).

2-132