SECTION V: TROUBLESHOOTING

TM 9-2350-256-20

WARNING

Remove all jewelry such as rings, dog tags,

bracelets, etc. If jewelry contacts a metal surface

a direct short may result in instant heating of

tools, damage to equipment, and injury or death

to personnel.

C

Reconnect wire 27E to transmission oil pressure gage.

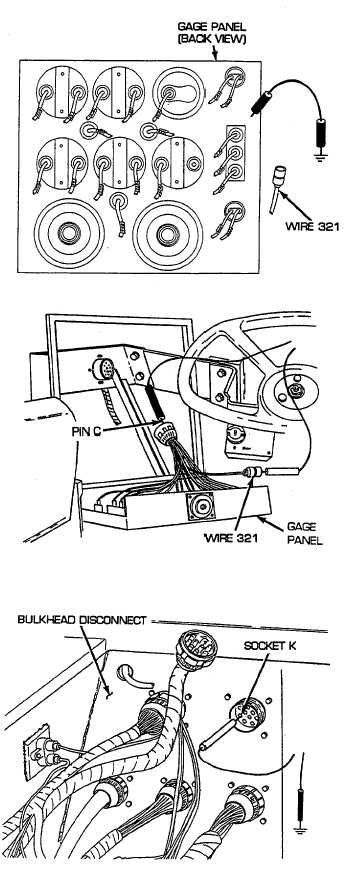

Disconnect wire 321 from transmission oil pressure

gage.

Turn

MASTER

switch

on

and

check

transmission

oil

pressure

gauge

for

operation.

Transmission oil pressure gage should read full scale.

Ground case of transmission oil pressure gage and

check gage for operation. Gage should read "O."

Turn MASTER switch OFF. If transmission oil

pressure gage reads correctly, go to step D. If

transmission oil pressure gage fails to read correctly,

replace transmission oil pressure gage (see paragraph

6-8).

D

Disconnect gage panel to bulkhead wiring harness

from gage panel. Check wire 321 in gage panel

harness for continuity by placing red lead of

multimeter on wire 321 and black lead on pin C. If

continuity is present, go to step E. If continuity is not

present, repair/replace wire 321 of gage panel wiring

harness (see paragraph 6-44).

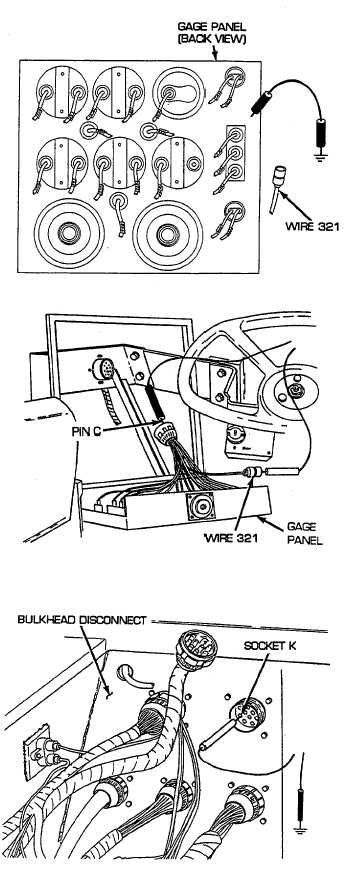

E

Reconnect wire 321 to transmission oil pressure gage

and bulkhead wiring harness to gage panel. Install

ground strap (5), two lockwashers (4), two screws (3),

gage panel (6), three lockwashers (2), and three

screws (1). Open air inlet doors (TM 9-2350-256-10).

Disconnect bulkhead to engine bracket and rear fuel

tank wiring harness from bulkhead disconnect. Place

red lead of multimeter in socket K of wire 321 and

black lead to ground. Turn MASTER switch on and

check for voltage. Turn MASTER switch OFF. If

voltage is present, go to step F. If voltage is not

present, repair/replace wire 321 of gage panel to

bulkhead wiring harness (see paragraph 6-45 for dual

voltage; 6-46 for single voltage).

2-121