SECTION III: PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

TM 9-2350-256-20

TABLE 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR THE MSBA1

Location

Item To

Not Fully

Item

Check/

Mission

No.

Interval

Service

Procedure

Capable If:

1

S

Fenders

Inspect for dents, cracks, breaks, or other damage.

2

S

Tracks

a. Check track adjustment and adjust as necessary.

S

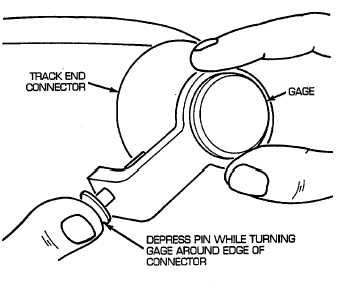

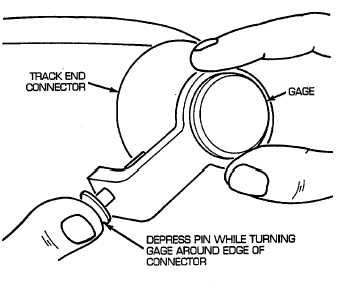

b. Check end connectors for wear using end connector

wear gage. Proceed as follows:

(1) Place locator of end connector wear gage

(Appendix C, item 15) over protruding end of track

link pin.

(2) Depress pin of gage and observe whether pin

touches end connector.

(3) Rotate gage around end surface of connector and

measure wear in various locations.

End

(4) If end of gage pin fails to touch surface of connector

connector

at any point when gage is fully depressed, end

unservice-

connector is excessively worn and must be

able

replaced.

2-9