TM 9--2350--292--20--2

0461 00--7

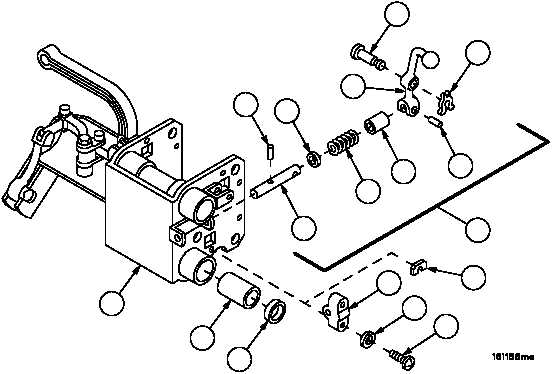

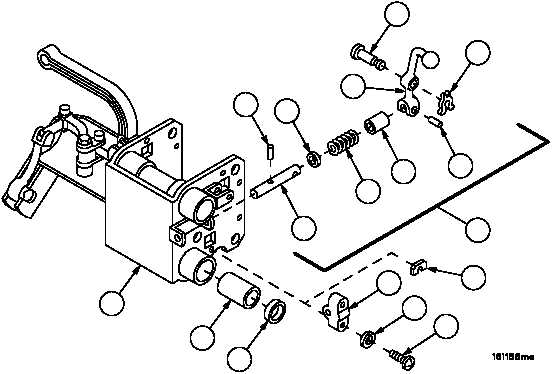

DRIVER’S AND MECHANIC’S SEAT REPAIR -- CONTINUED

0461 00

Disassembly--Continued

NOTE

Bearings are staked in adjusting assembly. Staked sur-

faces must be removed using grinder or file before bear-

ings can be removed.

25. Remove four plain encased seals (72) and four bearings (73) from adjusting assembly (67). Discard plain en-

cased seals.

NOTE

There are four side rollers mounted to adjuster assembly.

The procedures are the same for all four side rollers.

Note the quantity and position of shim(s) being removed

to ensure shim(s) are installed in the same position.

26. Remove two screws (74), two lockwashers (75), side roller (76) and shim(s) (77) from adjusting assembly (67).

Discard lockwashers.

27. Remove headless grooved pin (78), lock--release lever assembly (79), flat washer (80), spring (81) and spacer

(82) from adjusting assembly (63). Discard headless grooved pin.

28. Remove X--washer (83) and pin (84) from lock--release lever assembly (79). Discard X--washer.

29. Remove headless grooved pin (85) and lever (86) from shaft (87). Discard headless grooved pin.

67

73

72

76

75

77

79

82

81

87

78

80

86

84

85

83

74