TM 5-4240-501-14&P

Starter motor armatures have very low resistance.

Usually below detection on available multimeters (volts-

amperes- ohms). To check for shorted armatures, a

piece of equipment known as a "growler" may be used.

If this equipment is not available, a known good armature

should be used and performance checked.

If the magnets are suspect, a new motor housing should

be tried to test motor performance.

ASSEMBLY OF STARTER MOTOR

When all parts have been thoroughly inspected, lightly

lubricate bearings with a #20 oil and reassemble in the

following manner.

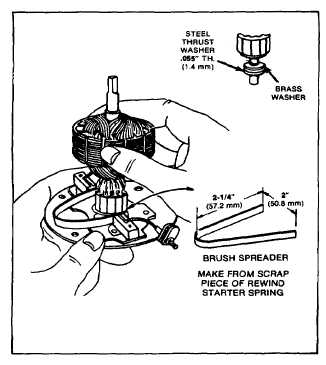

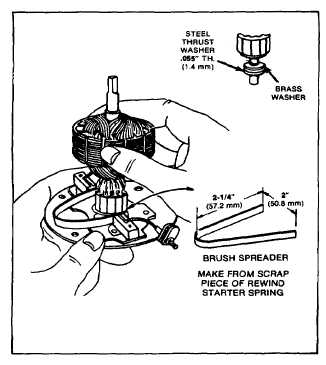

Insert brush springs and brushes in holders as far as

possible, and hold them in this position with tool shown in

Fig. 59. Place thrust washers on armature shaft, using

care to insure brushes clear commutator, slide armature

shaft into end cap bearing. See Fig. 59.

Fig. 59 - Assembling Armature to End Cap

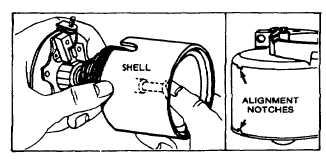

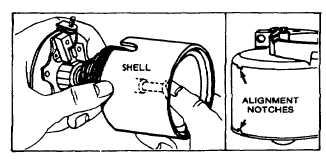

Support armature shaft and slide it slowly into starter

housing, as shown in Fig. 60. Insert rubber mounted

terminal into starter, housing at this time.

STARTERS

Nicad System

Fig. 60 -- Inserting Armature

Place remaining thrust washers on motor PTO shaft,

install end head cover and thru bolts. Notches in end

cap, housing and end head must be aligned. Fig. 60.

Check for end play to be sure armature is free. Slip

pinion and starter motor clutch gear on shaft, add a small

amount of gear lubricant to gears and install gear cover

and gasket. Fig. 61.

Fig. 61 - Lubricating Gears

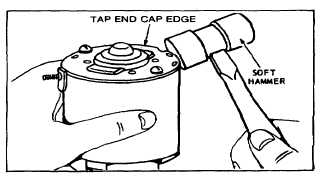

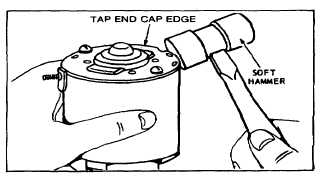

Tap end cap edge lightly using a soft hammer as this will

align the bearings. See Fig. 62.

Fig. 62 - Aligning End Cap Bearing

Replace nylon spur gear and retainer assembly. tighten

retainer screws securely. NOTE: Do not oil nylon spur

gear or clutch helix. Install starter cover. The starter

motor assembly is now ready

for re-installation to the engine.

15