TM 5-4270-501-14&P

STARTERS

Nicad System

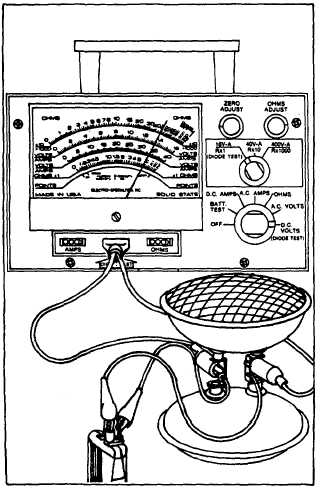

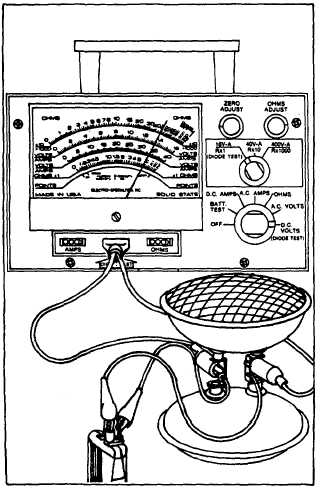

Fig. 51 - Battery Charger Tester

A fully charged battery, when connected to this headlight

set up will light the bulbs brightly for at least five minutes.

The voltmeter reading should be 13.5 volts minimum

after one minute, using the headlight load. A voltmeter

reading of 13 volts, or less, within a one minute period

indicates a defective cell in the battery. Replace battery.

NOTE: The battery must be in a fully charged condition,

prior to the above test. If the battery is not fully charged,

it will require charging for a 14 to 16 hour period before

proceeding with the above test. This voltmeter test is

valid only after a one minute period, when using the

lights as a load, because the voltage continues to drop

slowly throughout most of the test.

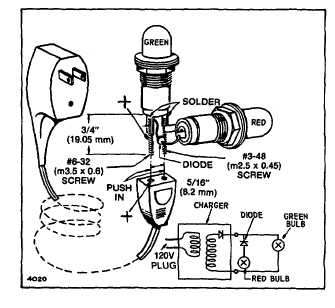

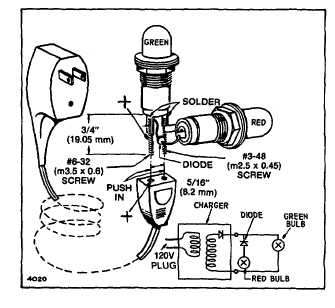

BATTERY CHARGER TESTER

The parts needed to construct a battery charger tester

are as follows. (See following for parts ordering

information.)

1.

One IN4005 diode.

2.

Two lamp sockets, such as a Dialco #0931-102,

red color and a #0932-102, green color.

3.

Two #53 bulbs.

4.

One #6-32, 3/4" long screw (m3.5 x 0.6).

5.

One #3-48, 3/4" long screw (m2.5 x 0.45).

These components are soldered together as shown in

the accompanying illustration, Fig. 52. if desired, these

components may be fitted to a plastic case.

The test procedure is as follows:

Plug the charger into a 120 volt AC outlet, known to be

good, connect the other end of the charger to the tester.

A charger in good condition will light the green bulb only.

If neither bulb lights, or both bulbs light, the charger

would be defective.

NOTE: The component parts for this tester may be

purchased at any radio supply parts house.

Fig. 52 - Battery Tester

KEY SWITCH TEST

The equipment needed to test the key switch is as

follows: Briggs & Stratton meter #19236 or equivalent

ohmmeter.

Test key switch as noted in Fig. 53. Replace switch if

not as shown under column, "Check Continuity."

12