TM 5-4240-501-14&P

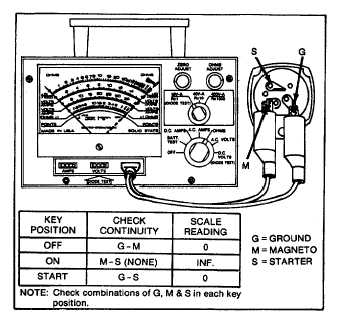

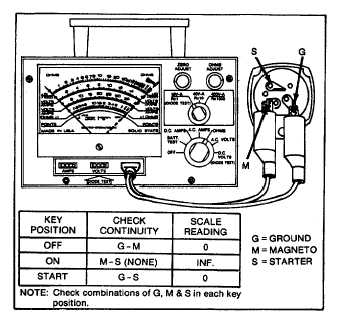

Fig. 53 - Starter Key Switch

CHECKING THE STARTER MOTOR

DRIVE AND CLUTCH

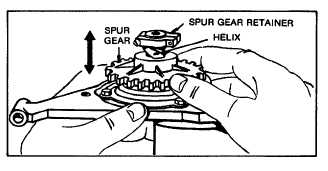

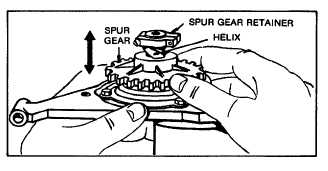

When the starter switch is activated, the nylon spur gear

should rise, engaging the flywheel ring gear, and crank

the engine. This action can be observed by removing

the starter cover. If the starter motor drive does not

react properly, inspect the helix and the nylon spur gear

for freeness of operation. If any sticking occurs, this

must be corrected. Proper operation of the starter is

dependent on the nylon spur gear freely moving on the

helix. See Fig. 54.

NOTE: Do not oil nylon spur gear or clutch helix.

Fig. 54 - Starter Motor Drive

The starter motor clutch is designed to prevent damage

from shock loads such as an engine backfire. The clutch

should not slip during normal engine cranking. This can

be checked by blocking the mower blade and engaging

the starter motor. If the clutch assembly slips at this

time, it should be replaced.

STARTERS

Nicad System

CAUTION: Remove spark plug high tension wire prior to

this test if starter motor is mounted on engine.

CHECKING THE STARTER MOTOR

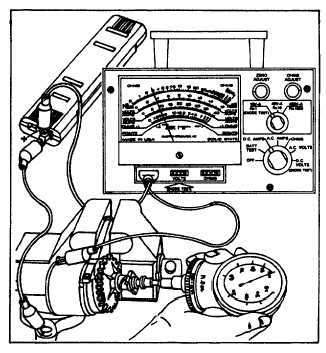

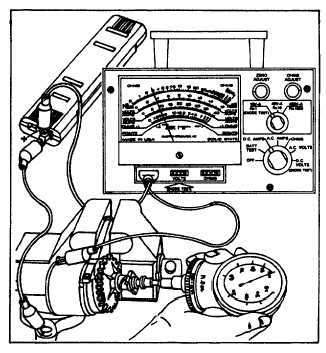

A performance test of the starter motor may be made in

the following manner.

Equipment Needed -

A tachometer capable of reading 1500 RPM.

An ammeter capable of reading 0 to 5 amps.

A fully charged battery.

Connect the starter motor, battery and ammeter, as

shown in the illustration. See Fig. 55.

Insert the tachometer in the end of the starter clutch helix

and activate the starter motor.

Fig. 55 - Performance Test

A starter motor in good condition will be within the

following specifications. Starter Motor RPM - 1000

minimum Current - 31/2 Amperes maximum If the starter

motor does not perform satisfactorily, the following

should be checked, and corrected if necessary.

1.

A binding condition between the pinion and clutch

gear or misalignment of motor bearings.

13