TM 9-2350-238-10

OPERATING CRANE–CONTINUED

LEVEL WIND OPERATION

The level wind assembly contains two sens-

ing switches that automatically actuate cab

hydraulic traversing system when tow winch

wire rope is not straight out from tow winch

drum. This action makes sure that there is a

perfect wire rope layup on tow winch drum.

The level wind sensing switches are activated

by level wind switch in cab. When level wind

switch is ON, turning level wind wire rope

slide will automatically traverse cab. There is

no electrical danger to personnel.

1

2

3

4

5

6

Start hydraulic system. Refer to page

2-67.

Open tow winch access door and

operate tow winch to pay out 10 to 15

ft (3.05 to 4.57 m) of wire rope. Refer

to page 2-79.

Adjust level wind, if out of adjustment.

Refer to page 3-51.

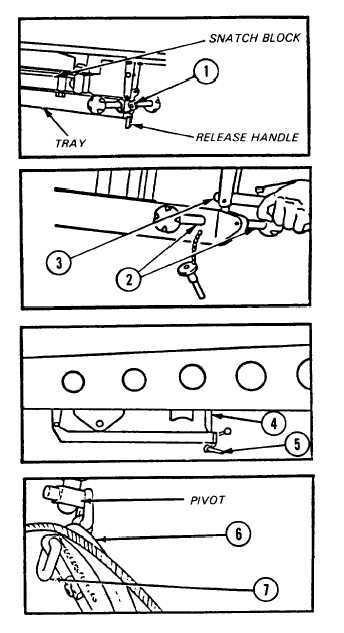

Remove quick release pin (1 ) securing

snatch block tray release handle.

Lift up on tray lift handles (2) to support

snatch block weight (approximately 90 lb

(40.8 kg)) and pull tray release handle

(3) to release tray and snatch block.

Lower tray and snatch block. Swing tray

up toward front of boom and secure to

bracket (4) on underside of boom with

quick release pin (5).

l Always wear leather gloves

(item 31, appx B) when han-

dling winch cable. Never

allow cable to run through

hands. Broken wires can

cause painful injuries.

l Any kinks, crushed sections,

or broken strands are poten-

tial weak points and can

cause wire rope failure.

Frayed, kinked, worn, or cor-

roded ropes must be replaced.

Rope is unsafe if three

broken wires are found in

one strand of 6 x 7 rope, six

broken wires in one strand of

6 x 19 rope, or nine broken

wires in one strand of 6 x 37

rope.

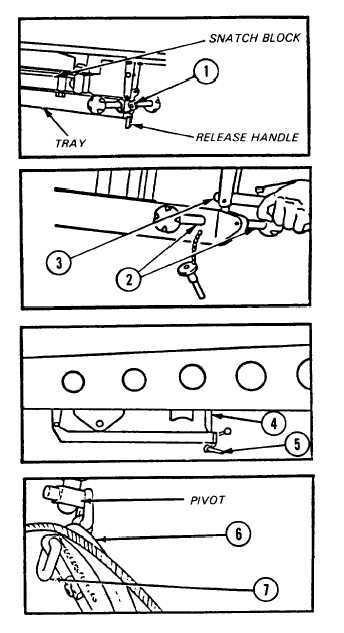

7 Pivot snatch block sheave (6) to aline

with tow winch wire rope. Lift snatch

block and release shackle (7) from pivot.

Place tow winch wire rope on snatch

block sheave and reinstall shackle on

pivot.

2-81