CHAPTER 2: VEHICLE MAINTENANCE INSTRUCTIONS

TM 9-2350-256-20

2-19 ELECTRICAL TROUBLESHOOTING-Continued

HYDRAULIC RESERVOIR MONITORING SYSTEM SWITCHES AND LIGHTS-Continued

WARNING

Remove all jewelry such as rings, dog tags,

bracelets, etc. If jewelry contacts a metal

surface a direct short may result in instant

heating of tools, damage to equipment, and

injury or death to personnel.

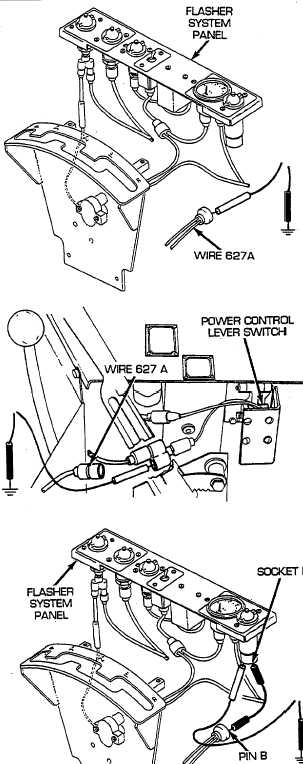

A

Disconnect flasher system panel wiring harness from

hydraulic oil high temperature light. Place red lead of

multimeter in socket B of wire 627A and black lead to

ground. Turn MASTER switch on, place power control

lever switch in ON position, and check for voltage. Turn

MASTER switch and power control lever switch OFF. If

voltage is present, go to step C. If voltage is not

present, go to step B.

B

Reconnect flasher system panel wiring harness to

hydraulic oil high temperature light. Disconnect wire

627A of flasher system panel wiring harness from Y-

connector at power control lever switch. Place red lead

of multimeter on Y-connector terminal and black lead to

ground. Turn MASTER switch on, place power control

lever switch in ON position, and check for voltage. Turn

MASTER switch and power control lever switch OFF. If

voltage is present, repair/replace wire 627A of flasher

system panel wiring harness from Y-connector to

hydraulic high temperature lamp (see paragraph 6-48).

If voltage is not present, troubleshoot power control

lever switch circuit.

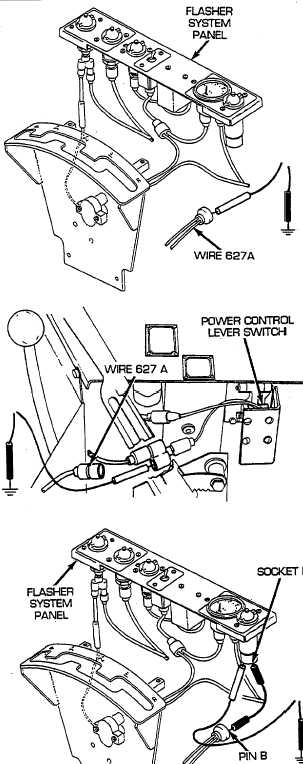

C

Place a jumper wire from socket B to pin B. Place red

lead of multimeter on terminal of hydraulic oil high

temperature light and black lead to ground. Turn

MASTER switch on, place power control lever switch in

ON position, and check for voltage. Turn MASTER

switch and power control lever switch OFF. If voltage is

present, go to step D. If voltage is not present, replace

hydraulic oil high temperature lamp (see paragraph 6-

11).

2-344