TM 9--2350--292--10

TRACK SHOE REPLACEMENT -- CONTINUED

0108 00

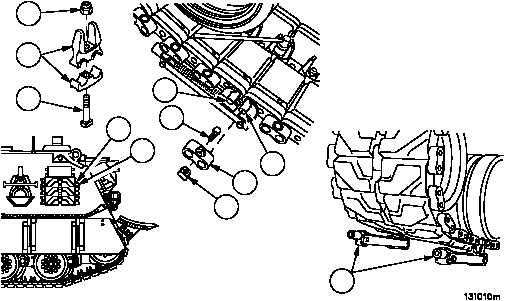

16. Remove nut (15), bolt (16), and track center guide (17).

17. Loosen the two track connecting fixtures (10) evenly.

18. Hold track up with tanker’s bar and remove track connecting fixtures (10).

19. Separate track.

20. Remove center guide (17) and end connectors (3) of track shoes to be replaced.

21. Remove track shoes from stowage by loosening nuts (18) and clamps (19).

22. Install center guide (17) and end connectors (3) on track shoes being replaced.

23. Hold track up with bar and install two track connecting fixtures (10).

24. Pull track together with track connecting fixtures (10) until center guide (17) can be installed.

25. Install center guide (17), bolt (16), and nut (15). Tighten bolt (16) and nut (15).

26. Using sledgehammer, install end connectors (3) on both sides of track shoe pins (12).

27. Remove track connecting fixtures (10).

28. Remove track binder (WP 0110 00).

29. Use sledgehammer to move end connectors (3) tight against track.

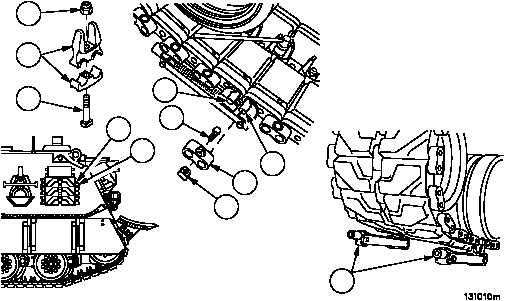

30. Install wedge (2) and bolt (1) in each end connector (3).

31. Move vehicle so track shoe assembly is starting over compensating idler wheel.

32. Tighten end connector bolt (1) in each end connector (3).

33. Adjust track tension (WP 0103 00 or WP 0104 00).

34. Close armor skirt plates #1, #3, #5 and #7 (WP 0102 00).

35. Notify unit maintenance that end connector and center guide bolts require torque as soon as possible. Torque

again after 50 miles.

10

1

2

3

18

19

15

17

16

12

12

END OF TASK

0108 00--3/4 blank