TM 9--2350--292--20--1

0097 00--10

BOOM FAILS TO OPERATE OR OPERATES ROUGHLY -- CONTINUED

0097 00

Q

Are hoses and fittings free of leaks and damage?

CONTINUED FROM STEP L

no

yes

CONTINUED ON NEXT PAGE

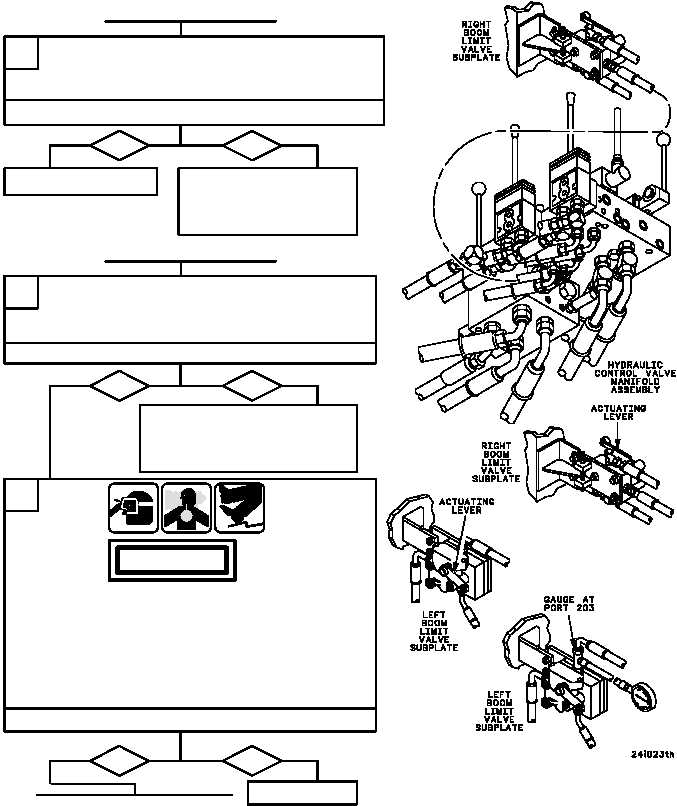

1. Remove subfloor plates 10, 11 and 12 (WP 0454 00).

2. Inspect hoses and fittings from hydraulic control

valve manifold assembly to right boom limit valve

subplate for leaks and damage.

Tighten leaking fittings.

Replace damaged hoses

and fittings (WP 0577 00).

Verify fault is corrected.

R

Are boom limit valve actuating levers free of binding?

no

yes

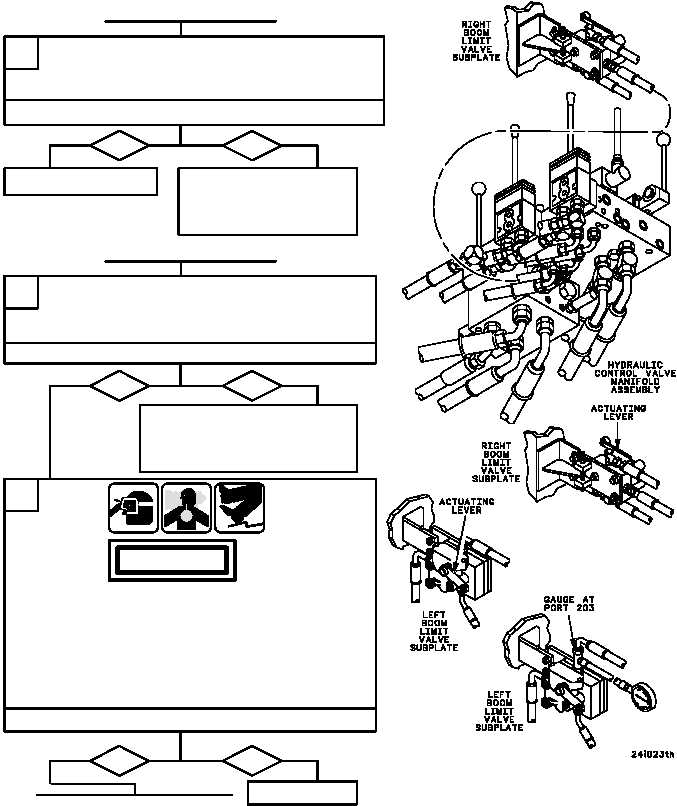

1. Remove air intake grilles beside both boom stayline

arms (WP 0415 00).

2. Inspect boom limit valve actuating levers for binding.

3. Shut down hydraulics and engine.

Free binding levers. Verify fault

is corrected. If levers cannot be

freed of binding, notify Direct

Support Maintenance.

Verify fault is corrected.

CONTINUED FROM STEP F

S

Is pressure 0 psi?

no

yes

1. Install a 0--4000 psi testing gauge assembly with

3/8--inch tee between left boom limit valve subplate

port 203 and attaching hose.

2. Start main engine, set speed to 1800 rpm, and

energize main hydraulics (TM 9--2350--292--10).

3. Read gauge and record pressure.

4. Shut down hydraulics and main engine

(TM 9--2350--292--10).

Go to Step X.

WARNING