TM 5-4240-501-14&P

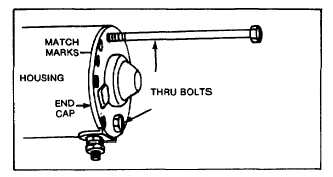

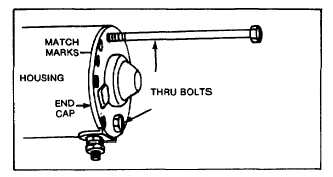

Fig. 75 - Removing Thru Bolts

CAUTION: Do not clamp the motor housing in a vise or

strike the motor housing with a hammer. These motors

contain two powerful ceramic magnets which can be

broken or cracked if the motor housing. is deformed or

dented.

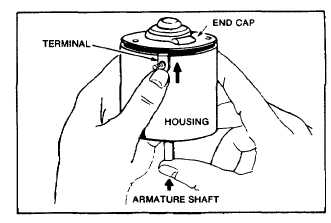

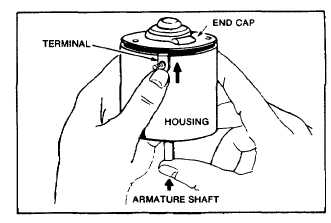

Remove armature and end cap as shown in Fig. 76. (If

120 volt motor, remove ground post with 1/4" nut driver

to free rectifier assembly. Fig. 79.)

Fig. 76 - Removing Armature

Clean all dirt or corrosion accumulations from the

armature, end cap, end head, etc. The bearings, motor

housing and armature should not be soaked in a

cleaning solution. The armature commutator may be

cleaned with a fine sand paper or commutator paper. Do

not use emery cloth, as emery will embed in the

commutator and cause rapid brush wear. If it is

suspected that the armature is defective, a new armature

should be tried in the motor. If proper testing equipment

is available, check the suspected armature to determine

if it is defective.

Starter motor armatures have very low resistance,

usually below detection on available multimeters (volt -

ampere - ohm). To check for shorted armatures, a piece

of equipment known as a "growler" may be used.

STARTERS

Gear Drive 12V & 120V

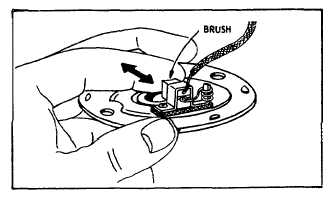

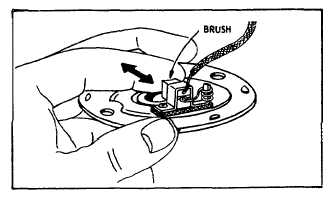

The brushes should be checked for poor seating, weak

brush springs, dirt, oil or corrosion. See Fig. 77.

If the magnets are suspect, a new motor housing should

be tried to test motor performance (Figs. 72 and 73).

Fig. 77 - Check Brushes

CHECKING THE RECTIFIER ASSEMBLY 120 VAC

STARTER MOTOR

Disconnect rectifier from end cap by removing leads

from terminals.

Test rectifier with multimeter (VOA meter, page 8) set on

resistance (R x 1 ohm) scale. Touch meter leads to red

and black rectifier lead, then reverse meter leads and

recheck. The meter should indicate a reading in one

direction only. Touch meter leads to black rectifier lead

shown in Fig. 79 and both AC posts, then reverse meter

leads. The meter should show a reading in one direction

only. Touch meter leads to red rectifier lead and both

AC posts. then reverse meter leads. The meter should

show a reading in one direction only.

If a meter reading is indicated in both directions or no

reading is indicated in either direction, the rectifier

assembly is defective and must be replaced.

ASSEMBLY OF STARTER MOTORS

When all parts have been thoroughly inspected, lightly

lubricate the bearings with #20 oil, and reassemble in the

following manner.

Insert the brushes in their respective holders. NOTE: A

tool such as shown in Fig. 45 and 78 should be used to

hold the brushes clear of the armature commutator when

assembling the armature to end cap.

21