TM 5-4240-501-14&P

Slip motor pinion gear on armature shaft. Add a small

amount of gear lubricant to gear teeth. Position gasket,

spring washer and drive housing assembly. Fig. 69.

Fasten drive housing to end head securely with three

screws. The starter motor assembly is now ready for

installation to the engine.

GEAR DRIVE STARTERS

120 VOLT AC; 12 VOLT DC

STARTER MOTOR - USED ON MODEL

SERIES: 170000, 190000, 220000, 240000,

250000 and 320000.

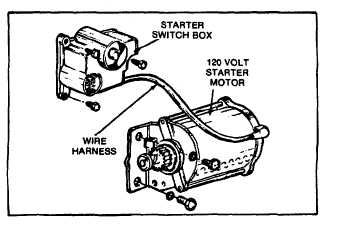

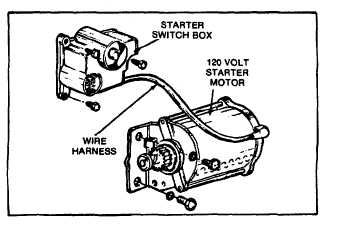

The 120 volt electric starter is equipped with a three-

prong plug for safety. The longer prong in this plug is

connected to the starter motor housing. When the

starter motor is plugged into the three-wire cord supplied,

and the cord is plugged into a properly grounded

receptacle, it will protect the user from shock should the

starter-motor insulation fail for any reason. If a longer

extension cord is used with this starter, it should also

have three-prong and three-hole plugs. Fig. 68. DO

NOT USE extension cords longer than 25 feet (7.62 m).

These starter motors use a gear type engagement

method, similar to an automobile starter. When the

starter motor is activated, the helix on the starter motor is

activated, the helix on the starter motor shaft drives a

pinion gear into engagement with a ring gear attached to

the engine flywheel and cranks the engine.

CAUTION: 120 volt starter motor should first be Hi-Pot

tested before re-assembly to engine to determine if a

shock hazard exists.

Fig. 82 - 120 Volt Gear Drive Starter

Briggs & Stratton STARTERS

Gear Drive 12V & 120V

CAUTION: DO NOT run starter motors for more than

one minute without cooling 15 minutes.

It is recommended a battery of 32 ampere hour capacity

be used with the 12 volt starter. The battery cable size

should be #4 or #6.

NOTE: A battery of higher amperage may be required for

extremely cold weather starting conditions.

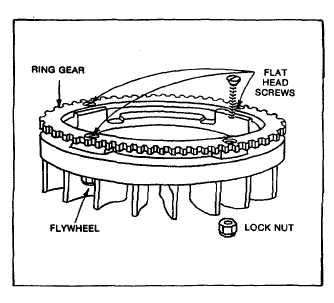

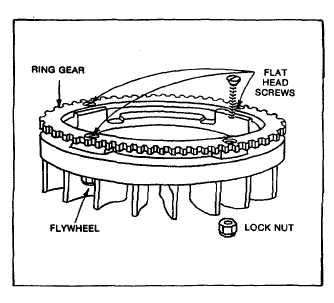

Replacing a Ring Gear

To replace a worn or damaged flywheel ring gear,

proceed as follows:

A steel ring gear must be used on the flywheel if the

pinion gear on the starter motor is made of steel, An

aluminum ring gear must be used on the flywheel if the

pinion gear on the starter motor is made of nylon.

Fig. 83 - Replacing Ring Gear

WARNING: DO NOT strike flywheel with a hard object or

metal tool as this may cause flywheel to shatter in

operation, causing personal injury or property damage.

23