TM 5-4240-501-14&P

STARTERS- Briggs & Stratton Gear Drive 12V & 120V

Equipment Needed -

1.

An AC volt meter capable of measuring 120

volts AC.

2.

An AC ammeter capable of measuring 25

amperes AC.

3.

A VOA meter as shown on page 20 may be

used in place of volt meter and ammeter noted above.

4.

Remove the spark plug from the engine.

CAUTION: The test of this rectifier assembly requires the

use of a 120 volt AC circuit. Extreme care should be

used when making this test to minimize the hazard of

electrical shock.

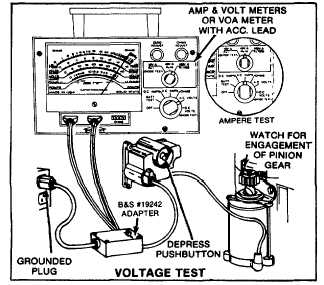

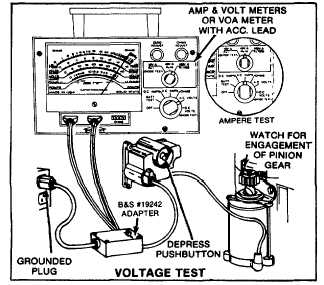

Measure the line voltage of the 120 volt AC outlet to be

used. Connect the voltmeter and ammeter as shown in

Fig. 99 prior to removal from engine.

Fig. 99 - Checking Control Assembly Performance

A control assembly in good condition will show 120 volts

of line voltage and a maximum of 15 amperes on the

ammeter with starter button depressed and starter motor

engaged. Fig. 99 inset.

If meters show no readings or a reading of 20 amperes

is exceeded, see Troubleshooting, page 9 and 10.

DISASSEMBLING CONTROL ASSEMBLY

DANGER: Disconnect extension cord from outlet before

disassembling control assembly.

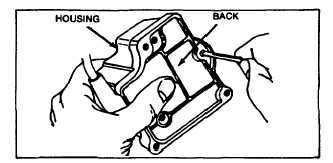

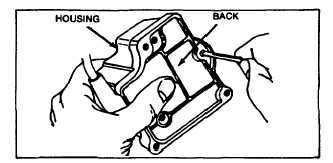

With control assembly removed from mounting surface,

remove three screws holding back plate to housing. Fig.

100. Note position of wires.

Fig. 100 - Removing Back Plate

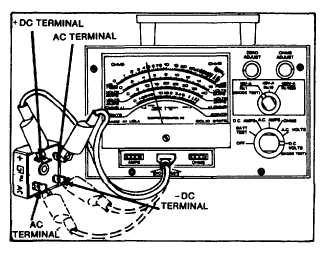

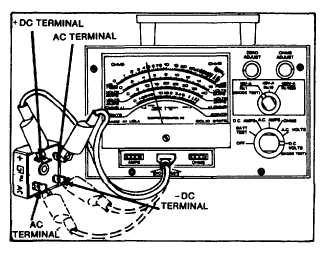

Disconnect wires from rectifier.. Test rectifier as shown

in Fig. 101. With one probe on (+) plus terminal, touch

three remaining terminals with other probe. Reverse

procedure. Place other probe on (+) terminal and touch

three terminals with probe. One test should not indicate

any reading.

Fig. 101 - Checking Rectifier

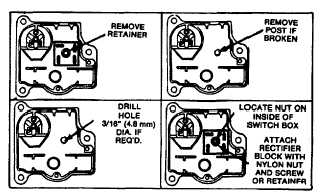

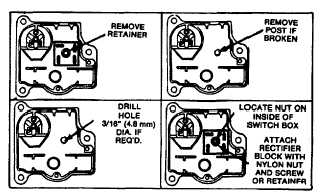

To replace rectifier assembly, remove retainer spring

washer. Note rectifier position and remove. If rectifier

post should break, drill a 3/16" diameter hole in post

location. Connect rectifier with plastic screw and nut.

Assemble as noted in Fig. 102 and 104.

Fig. 102 - Replacing Rectifier

28