TM 5-4240-5501-148P

STARTERS

Gear Drive 12V & 120V

Checking Starter Motors

If a starting problem is encountered, check the engine

thoroughly to be sure it is not the cause of starting

difficulty. It is a good practice to remove the spark plug

and rotate the crankshaft by hand, to be sure it rotates

freely. Any belt, clutch or other parasitic load will affect

cranking performance.

Service procedures for both the 12 volt and 120 volt

starter motors are similar and will be covered together,

except where noted otherwise.

A list is provided to aid in diagnosing problems for 12 volt

DC and 120 volt AC systems. See page 9 and 10.

CHECKING STARTER MOTOR DRIVE

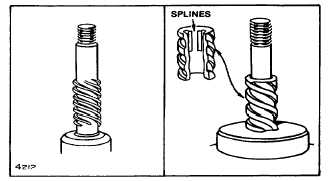

When the starter motor is activated, the pinion gear

should rise, engaging the flywheel ring gear and crank

the engine. This action can be observed by removing

the starter shield. If the starter motor drive does not

react properly, inspect the helix and pinion gear for

freeness of operation. If any sticking occurs, this must

be corrected. Proper operation of the starter is

dependent on the pinion freely moving on the helix. See

Fig. 109.

Fig. 109 - Checking Starter Motor Drive

DISASSEMBLING STARTER MOTOR DRIVE

To

remove

the

drive

assembly

for

cleaning

or

replacement, clamp the pinion gear in a vise having

brass jaws, to prevent damage to the gear teeth. The

lock nut may then be removed and the starter drive

disassembled for cleaning or replacement.

The pinion gear should be inspected for damaged teeth.

If a sticking condition exists between the pinion gear and

the helix, the parts may be washed in a solvent such as

Stanasol or Varsol. If the sticking condition is not

corrected by cleaning, the complete drive assembly must

be replaced. Individual parts of the drive assembly are

not available.

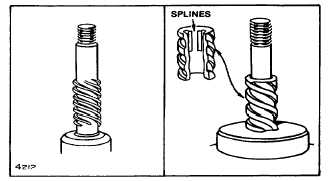

ASSEMBLING STARTER MOTOR DRIVE

Reverse disassembly procedure for assembling. The

interior of the shaft screw has a spline machined to the

center; when assembling, the spline must face the end of

the armature shaft. See Fig. 110. Torque the lock nut

to 170 inch pounds (19.2 Nm). This torque has an effect

on pinion travel, so proper torque should be maintained.

NOTE: Do not lubricate Drive Assembly.

NOTE: For starter motors equipped with nylon pinion

gear, page 24 and 25 contains assembly and repair

information.

Fig. 110 - Assembling Starter Motor Drive

If sticking occurs during freezing weather, spray

a dry silicone spray on helix.

CHECKING STARTER MOTOR

PERFORMANCE

120 VOLT AC STARTER MOTORS

A performance test of the 120 volt starter motor may be

made in the following manner.

Equipment Needed

1. A tachometer capable of reading 10,000 RPM.

2. An ammeter capable of reading 0 to 10 amperes.

31