TM 5-4240-501-14&P

STARTERS

Gear Drive 12V & 120V

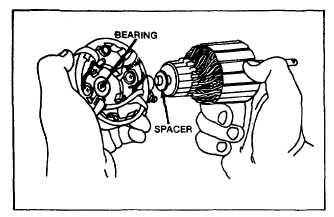

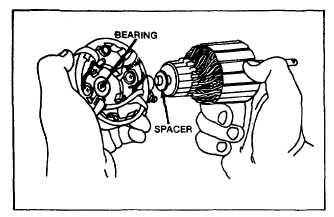

Fig. 107 - Assembling Armature to End Cap

Slide motor housing over armature with the notch toward

commutator end cap. Match alignment marks. Fig. 94.

Care should be used to prevent damage to magnets in

motor housing during assembly. Assemble spacers and

drive head end bracket, again aligning match marks.

Armature end play is .006 to .038" (.15 to .97 mm) after

assembly.

Assemble thru bolts and washers. Torque thru bolts, 45

to 55 inch pounds (5.1 to 6.2 Nm) for 1/4- 20 thru bolts

and 40 to 45 inch pounds (4.5 to 5.1 Nm) for 10-24 thru

bolts.

HIGH POTENTIAL (HI-POT) TEST -

120 VAC (ONLY)

Before anc after repairing the 120 volt AC starter motor,

a Hi-Pot test must be made to prevent injury. If the

proper test equipment is not available, take the starter

motor to a qualified electric motor repair shop for testing.

After assembly of the starter motor drive and Hi-Pot test

is passed, the starter motor is now ready for installation

to the engine.

GEAR DRIVE STARTERS

120 VOLT AC; 12 VOLT DC

STARTER MOTOR - USED ON SERIES

140000, 170000 and 190000

These starter motors use a gear type engagement

method, similar to an automobile starter. When the

starter motor is activated, the helix on the starter motor

shaft drives a pinion gear into engagement with a ring

gear attached to the engine flywheel and cranks the

engine.

Electrical shock is always a hazard with any electrical

equipment. To minimize the hazard of electrical shock,

the 120 volt starter motor is provided with a three wire

power source connection. To maintain the safety

provided against electrical shock, the extension cord

used between the starter motor and the power source

must be a three wire cord, which connects to a properly

grounded receptacle. DO NOT USE power cords longer

than 25 feet.

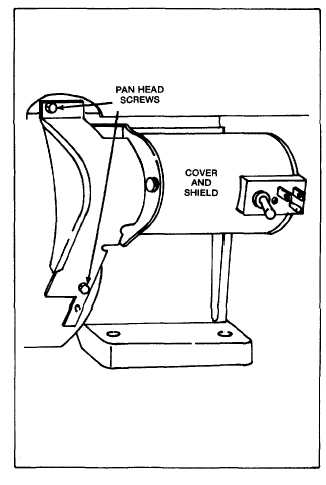

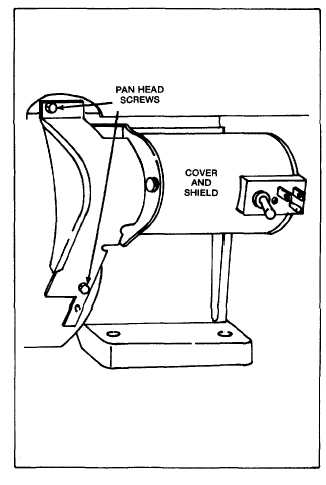

Fig. 108 - 120 Volt Gear Drive Starter Motor

CAUTION: DO NOT run starter motor for more than one

minute without cooling 15 minutes.

It is recommended a battery of 32 ampere hour capacity

be used with the 12 volt starter. The battery cable size

should be #4 or #6. Note: A battery of higher amperage

may be required for extremely cold weather starting

conditions.

Replacing a Ring Gear

To replace a worn or damaged flywheel ring gear, see

page 23, Fig. 82.

30