TM 5-4240-5501-148P

STARTERS

Gear Drive 12V & 120V

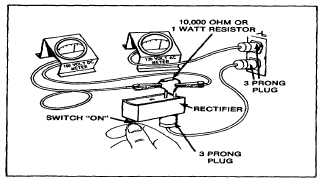

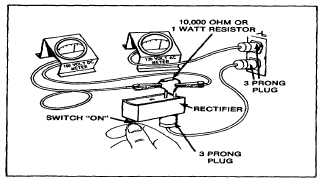

CAUTION: The test of this rectifier assembly requires the

use of a 120 volt AC circuit. Extreme care should be

used when making this test to minimize the hazard of

electrical shock.

Solder the 10,000 ohm resistor to the DC internal

terminals of the rectifier, as shown in the accompanying

illustration. Fig. 119.

Fig. 119 - Checking Rectifier Assembly

Connect the DC volt meter between the rectifier field

terminal and the brush terminal. Fig. 119.

Measure the line voltage of the 120 volt AC outlet to be

used. A rectifier assembly in good condition will be

within the following specifications: 1. With the switch in

the off position, a zero reading should be observed on

the DC volt meter.

2. With the switch in the on position, the DC volt meter

reading should be 0 to 14 volts lower than the AC line

voltage measured previously.

If the drop exceeds 14 volts, the complete rectifier

assembly must be replaced, as individual parts for the

rectifier assembly are not available.

ASSEMBLY OF STARTER MOTORS

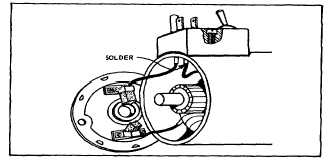

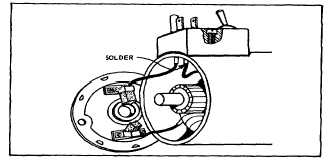

When all parts have been thoroughly inspected, lightly

lubricate the bearings with #20 oil and reassemble in the

following manner. (Solder the field lead to the rectifier

assembly and assemble the rectifier to the housing (120

VAC motor). Fig. 120.

Fig. 120 - Installing Rectifier to Housing

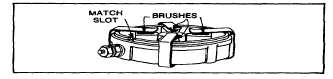

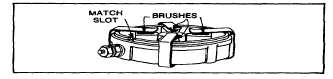

Insert the brushes in their respective holders.

NOTE: A tool such as shown in Fig. 45 should be used

to hold the brushes clear of the armature commutator

when assembling the commutator end cap to the motor

housing.

Fig. 121 - Inserting Brushes

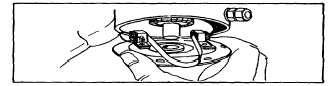

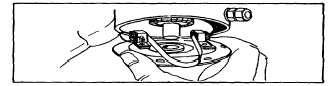

Fig. 122 - Installing End Cap

Slide the armature into the motor housing, being sure to

match the drive end cap keyway to the stamped key in

motor housing. Assemble end cap, again matching the

keyway to key in housing. Care should be used to

prevent damage to ceramic magnets where used.

Assemble thru bolts, lockwashers and nuts.

NOTE: THRU BOLTS AND NUTS MUST BE PLACED

IN THE SAME POSITION AS WHEN REMOVED OR

INTERFERENCE MAY RESULT.

After Hi-Pot test and assembly of the starter motor drive,

the starter motor is now ready for installation to the

engine.

35